Top 10 Benefits of Robotic Plasma Cutting for Manufacturing Efficiency

In the competitive landscape of modern manufacturing, businesses are continually seeking innovative technologies to enhance efficiency and precision. One such advancement that has garnered significant attention is robotic plasma cutting. According to a recent report by Industry Week, robotic plasma cutting can increase production rates by up to 50% while reducing material waste by nearly 30%. These remarkable statistics underline the transformative potential of this technology in optimizing manufacturing processes.

Experts in the field, such as Dr. Emily Tran, a leading researcher in automation technologies, emphasize the importance of robotic plasma cutting in revolutionizing fabrication methods. As she aptly stated, “The integration of robotic plasma cutting not only streamlines operations but also ensures a level of accuracy that manual processes simply cannot achieve.” By harnessing the power of automation, manufacturers can improve turnaround times and deliver higher quality products, ultimately positioning themselves for success in an ever-evolving marketplace.

The benefits of robotic plasma cutting extend beyond mere efficiency; they encompass enhanced safety, lower operating costs, and increased design flexibility. As manufacturing industries globally look to adopt cutting-edge solutions, understanding the numerous advantages of robotic plasma cutting becomes crucial for maintaining a competitive edge. This consideration marks the beginning of a deeper exploration into the top ten benefits of this innovative technology.

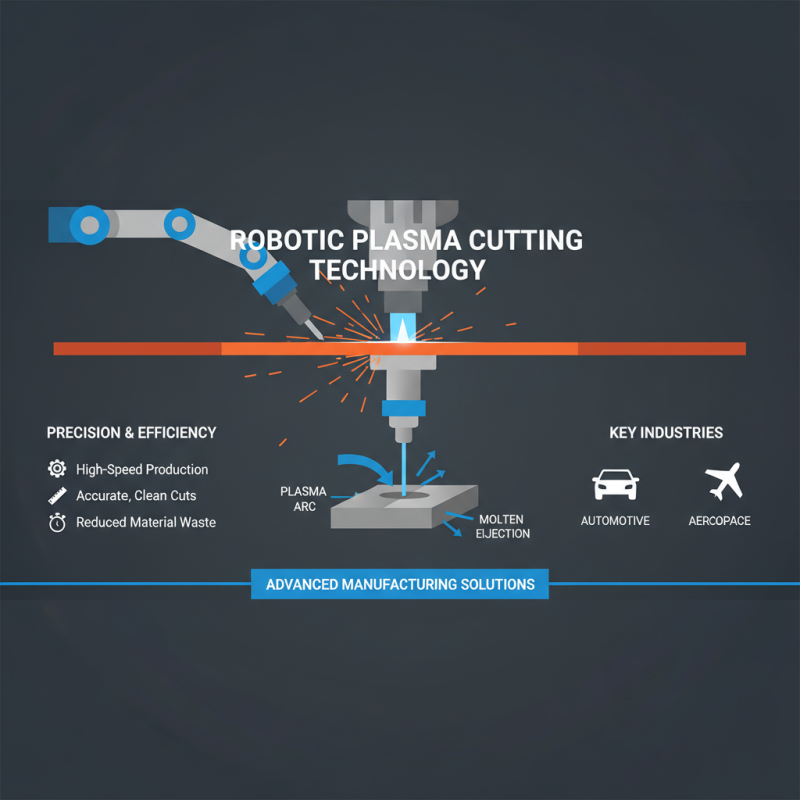

Overview of Robotic Plasma Cutting Technology

Robotic plasma cutting technology represents a significant advancement in the field of manufacturing. Utilizing high-temperature plasma to cut through various materials with precision, this technology enhances the overall efficiency of production processes. The mechanism operates by delivering a concentrated arc of ionized gas, which rapidly melts the material while a high-velocity jet blows the molten metal away from the cut. This method is particularly effective for thick metals, ensuring clean and accurate cuts that are essential in industries such as automotive and aerospace.

Incorporating robotic systems into plasma cutting improves not only the speed and accuracy of cuts but also the flexibility of production lines. Robots can be programmed to perform complex cutting patterns with minimal human intervention, leading to decreased labor costs and reduced potential for human error. Additionally, the integration of advanced software allows manufacturers to optimize cutting paths and reduce material waste, contributing to a more sustainable production environment. As industries continue to seek innovative ways to enhance manufacturing efficiency, robotic plasma cutting stands out as a revolutionary solution, combining technological sophistication with practical benefits.

Enhanced Precision in Material Cutting and Shaping

Robotic plasma cutting technology has revolutionized the manufacturing landscape, particularly in its ability to enhance precision in material cutting and shaping. According to a report by MarketsandMarkets, the global market for plasma cutting equipment is expected to reach $6.75 billion by 2025, indicating a robust adoption of this technology across various industries. This precision is crucial as it allows for tighter tolerances, resulting in high-quality finished products that meet stringent specifications. By employing advanced robotic arms and sophisticated control systems, manufacturers can achieve repeatable accuracy that manual cutting methods simply cannot match.

The accuracy offered by robotic plasma cutting is underscored by empirical studies, which show that the use of robotic systems can reduce material wastage by as much as 30%. Precision in cutting translates to less scrap material, significantly lowering costs and reducing the environmental impact associated with excess waste. Furthermore, the automated nature of plasma cutting systems enables manufacturers to optimize their workflow. According to a report by the International Federation of Robotics, automation in manufacturing processes, including cutting, can lead to productivity improvements of up to 25%. This increase in efficiency not only enhances overall production rates but also allows for more complex designs that would be challenging to achieve with traditional cutting methods, thus pushing the boundaries of innovation in manufacturing.

Increased Production Speed and Reduced Cycle Times

Robotic plasma cutting has revolutionized the manufacturing landscape, significantly enhancing production speed and reducing cycle times. This advanced cutting technique employs high-precision machinery that utilizes plasma torches to cut through metal with unparalleled speed. As a result, manufacturers can complete jobs in a fraction of the time compared to traditional cutting methods. The automation inherent in robotic systems ensures that processes are not only faster but also more consistent, reducing the variability that can often lead to delays in production.

Moreover, the agility of robotic plasma cutting allows for quick adjustments to be made in response to changes in design or production demands. This flexibility means that manufacturers can rapidly switch between different tasks without incurring the lengthy downtimes typically associated with retooling. As a direct outcome, companies benefit from increased throughput and improved efficiency, enabling them to meet tight deadlines and adapt to market shifts more effectively. Ultimately, the combination of speed and reduced cycle times positions robotic plasma cutting as a vital component in modern manufacturing strategies.

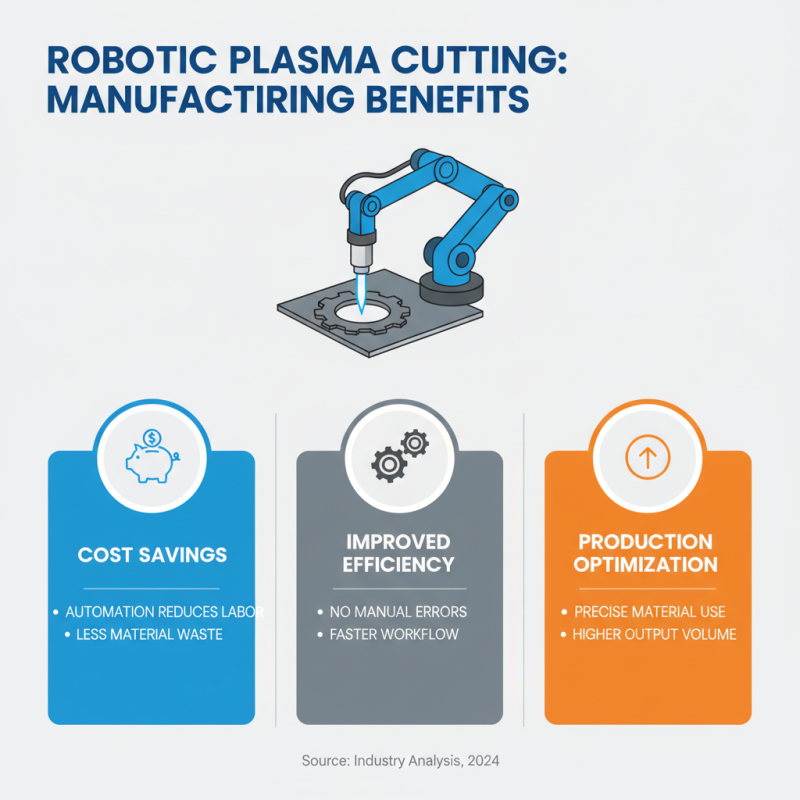

Cost Savings through Automation and Labor Efficiency

The integration of robotic plasma cutting technology in manufacturing processes significantly enhances cost savings through automation and improved labor efficiency. By employing robotic systems, companies eliminate manual cutting errors, reduce material waste, and streamline their workflows. This level of precision ensures that materials are utilized optimally, leading to lower costs in inventory and reducing the need for rework. Additionally, the automation of cutting processes allows manufacturers to take on larger production volumes without a corresponding increase in labor costs.

Moreover, robotic plasma cutting systems can operate around the clock with minimal supervision, freeing human resources for more skilled tasks where their expertise can be better utilized. This shift not only increases labor efficiency but also contributes to higher employee satisfaction, as workers can focus on more complex and value-added activities rather than repetitive and potentially hazardous tasks. The result is a more efficient manufacturing environment with reduced operational costs, paving the way for greater competitiveness in the market. As industries continue to embrace this technology, the financial benefits of automation become increasingly clear, underscoring the importance of robotic plasma cutting in modern manufacturing.

Improved Safety and Reduced Workplace Hazards

Robotic plasma cutting has revolutionized the manufacturing sector by significantly enhancing safety protocols and reducing workplace hazards. With the integration of advanced technology, these automated systems eliminate the need for manual cutting, which is often fraught with risks such as burns, cuts, and exposure to harmful fumes. Operators can control the robotic machines from a safe distance, minimizing their exposure to dangerous materials and processes. This shift not only reduces the likelihood of accidents but also fosters a culture of safety within manufacturing environments.

Furthermore, the precision and consistency of robotic plasma cutting contribute to a safer working atmosphere. These machines operate with remarkable accuracy, reducing the chance of material waste and the potential hazards associated with incorrect cuts. Enhanced accuracy leads to fewer mistakes, which not only streamlines operations but also mitigates risks related to faulty components or products. As manufacturers prioritize worker safety, the adoption of robotic plasma cutting stands out as an effective solution to create a more secure and efficient workplace.

Top 10 Benefits of Robotic Plasma Cutting for Manufacturing Efficiency

This chart illustrates the benefits of robotic plasma cutting in manufacturing, highlighting improvements in safety and reductions in workplace hazards.

Related Posts

-

Exploring the Future of Automation: How Robot Machines are Revolutionizing Industry Efficiency

-

What is Robotic Plasma Cutting? Transforming Manufacturing with 30% Speed Boost

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

What is Robotic Welding Solutions? Exploring Automation in the Welding Industry with Data Insights

-

Revolutionizing Learning How Robotic Training Enhances Skill Development and Employment Opportunities