Top 10 Benefits of Robotic Spot Welding in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, robotic spot welding has emerged as a game-changing technology that significantly enhances efficiency and precision in production processes. Dr. Jane Smith, a renowned expert in automation and robotics, emphasizes the transformative impact of this technique by stating, "Robotic spot welding not only optimizes manufacturing workflows but also ensures consistent quality, reducing defects and increasing overall productivity."

The adoption of robotic spot welding systems offers numerous benefits that can elevate manufacturing performance, from improved speed and accuracy to greater safety and operational flexibility. As industries strive to meet the demands of a competitive market, understanding these advantages becomes crucial. This article will explore the top ten benefits of robotic spot welding and how it can reshape manufacturing practices, fostering a new era of innovation and productivity.

As we delve into the specifics, it is important to recognize the pivotal role that robotic spot welding plays in driving efficiency and reliability across various sectors, paving the way for a smarter and more sustainable manufacturing future.

Advantages of Robotic Spot Welding for Precision Manufacturing

Robotic spot welding has become an integral part of modern precision manufacturing, offering several advantages that enhance efficiency and product quality. According to a recent study by the International Federation of Robotics, industries that implement robotic welding systems experience a productivity increase of up to 30% compared to traditional manual methods. This leap in productivity is primarily attributed to the high speed and consistency of robotic welding techniques, which significantly reduce the time required for each weld and minimize human error.

Furthermore, robotic spot welding ensures exceptional precision, crucial for industries where the integrity of joints is paramount. Reports from the American Welding Society indicate that automated welding processes can achieve a repeatability of ±0.5 mm, enhancing the accuracy of joins and reducing the likelihood of defects. This precision not only leads to higher quality products but also decreases material waste, contributing to cost savings and sustainability efforts in manufacturing. As companies strive for greater efficiency and reliability, the transition to robotic spot welding is proving to be a pivotal move in maintaining competitive advantage in precision manufacturing.

Top 10 Benefits of Robotic Spot Welding in Modern Manufacturing

| Benefit | Description | Impact on Production |

|---|---|---|

| Increased Precision | Robotic machines ensure consistent and accurate weld placements. | Reduces errors and rework, enhancing product quality. |

| Higher Speed | Robots can operate continuously, performing tasks faster than humans. | Increases overall production rates. |

| Reduced Labor Costs | Less reliance on manual labor leads to significant cost savings. | Improves profit margins for manufacturers. |

| Enhanced Safety | Reduces exposure of workers to hazardous conditions. | Promotes a safer working environment. |

| Flexibility | Easily programmable for various tasks and products. | Facilitates quick changes in production processes. |

| Consistent Quality | Automated welding provides uniform welds every time. | Enhances reliability of the final products. |

| Reduced Material Waste | Optimal welding techniques reduce scrap and rework. | Improves sustainability and reduces costs. |

| Workplace Ergonomics | Automating tough jobs can greatly improve workplace ergonomics. | Leads to higher employee satisfaction and reduced turnover. |

| Data Collection and Analytics | Robots can gather data for process improvement. | Facilitates ongoing optimization efforts. |

| Scalability | Easily scale up production with additional robotic units. | Supports growth initiatives without major overhead. |

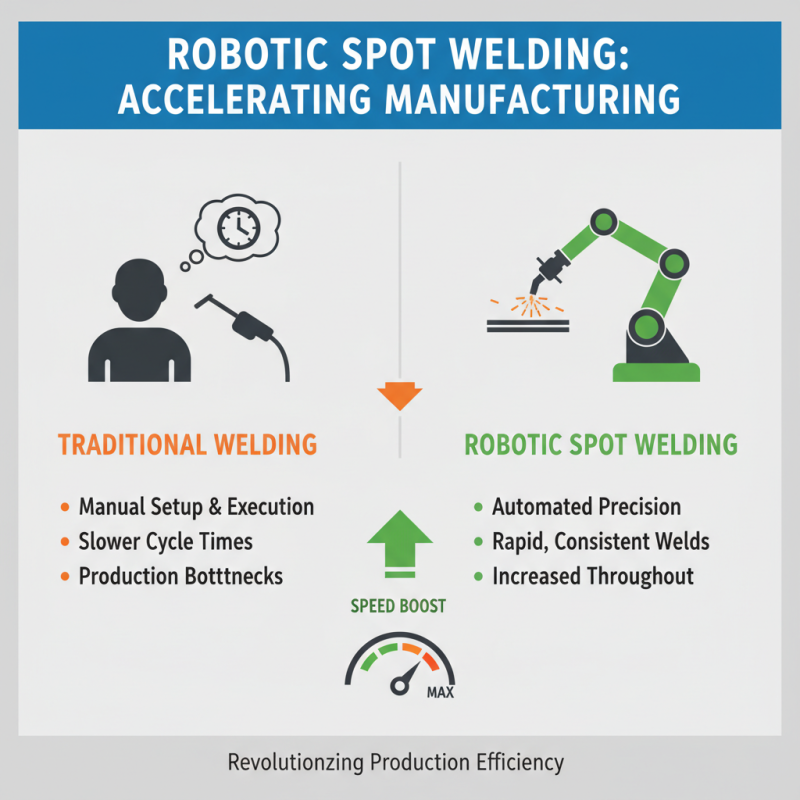

Enhanced Production Speed with Robotic Spot Welding Technology

Robotic spot welding technology has revolutionized the manufacturing landscape by significantly enhancing production speed. Traditional welding methods often require more time for setup and execution, leading to potential bottlenecks in the manufacturing process. In contrast, robotic systems can perform spot welding tasks with remarkable efficiency. These automated machines are equipped with precise programming and advanced sensors, allowing them to execute welds consistently and rapidly, reducing cycle times and increasing overall throughput.

Moreover, the integration of robotic spot welding not only accelerates production but also enhances quality control. Robots deliver uniform welds with a repeatability that is difficult to achieve with manual techniques. This consistency means fewer defects and rework, translating into faster production rates and more reliable output. As manufacturers seek to meet the rising demands for faster delivery and higher quality products, robotic spot welding stands out as a critical solution that not only boosts efficiency but also ensures the integrity of the welded components, thereby streamlining the manufacturing process overall.

Improved Consistency and Quality Control in Welding Processes

Robotic spot welding has become an essential component in modern manufacturing, particularly due to its significant contributions to

consistency and quality control in welding processes.

According to a report by the International Federation of Robotics, industries employing robotic automation in welding have seen a remarkable increase in production efficiency,

with some manufacturers reporting up to a 30% reduction in cycle times. This is largely attributed to robots' ability to perform repetitive tasks with the same

precision and accuracy, which minimizes human error and enhances overall welding quality.

The standardized nature of robotic spot welding systems allows for greater control over various parameters such as welding current, time, and pressure.

A study published by the American Welding Society highlights that these precise controls lead to a 50% decrease in defect rates

compared to traditional manual welding methods. As a result, manufacturers can achieve tighter tolerances and higher-quality welds, which are crucial in sectors like

automotive and aerospace where safety and integrity are paramount.

By ensuring a consistent weld quality, businesses can reduce rework costs and improve their bottom line.

Cost Efficiency and Reduced Labor Costs in Manufacturing

Robotic spot welding has revolutionized modern manufacturing by delivering significant cost efficiencies and reducing labor costs. One of the primary benefits of integrating robotic systems into the welding process is the optimization of resource allocation. Robots can operate continuously without breaks, minimizing downtime and maximizing throughput. This continuous operation allows manufacturers to maintain high production rates, ultimately reducing the cost per unit of output. Moreover, as robotic systems become more sophisticated, they require less oversight and management, further decreasing personnel expenses associated with traditional welding techniques.

In addition to direct labor savings, robotic spot welding enhances overall manufacturing efficiency. With precision and consistency, robots reduce the likelihood of defects and waste, leading to lower rework costs. Enhanced accuracy also allows for the integration of lighter and more innovative materials, which can contribute to further savings throughout the production process. By decreasing both the time and material costs associated with welding operations, manufacturers can improve their profit margins while remaining competitive in an increasingly demanding market.

Flexibility and Scalability of Robotic Spot Welding Applications

Robotic spot welding has emerged as a game-changer in modern manufacturing, particularly due to its inherent flexibility and scalability. One of the primary advantages of robotic spot welding is its adaptability to varying production requirements. Manufacturers can easily reprogram robots to handle different welding tasks, accommodating changes in product design or material types without significant downtime. This flexibility allows companies to swiftly respond to market demands, reducing lead times and improving overall efficiency.

Moreover, the scalability of robotic spot welding systems enables manufacturers to expand their operations with relative ease. As production volumes increase, additional robotic units can be integrated into existing workflows to enhance throughput without a complete overhaul of the system. This scalability is essential for businesses looking to grow while maintaining quality and consistency in their output.

The ability to ramp up production quickly and efficiently positions manufacturers to capitalize on new opportunities while keeping operational costs in check. With these benefits, robotic spot welding continues to play a pivotal role in shaping the future of manufacturing.

Related Posts

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency

-

How to Improve Your Robotic Welding Techniques for Better Results

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Revolutionize Your Manufacturing Process with the Latest FANUC Welding Robot Innovations

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency