How to Choose the Best Industrial Automation Solutions for Your Business Needs

In today’s fast-paced industrial landscape, investing in the right industrial automation solutions is crucial for businesses aiming to enhance efficiency, reduce operational costs, and improve overall productivity. With numerous options available on the market, the challenge lies in selecting solutions that align with specific business needs and operational goals. The implementation of automation technology can significantly transform processes, allowing companies to stay competitive and agile in their respective industries.

When considering industrial automation solutions, it is essential to conduct a thorough assessment of your current processes and identify areas where automation can provide the most value. This involves understanding the unique demands of your operations, as well as the flexibility and scalability required to adapt to future changes. By carefully evaluating these factors, businesses can make informed decisions that will not only optimize existing workflows but also pave the way for innovation and growth.

Ultimately, choosing the best industrial automation solutions is not just about selecting the latest technology; it's about finding a comprehensive approach that integrates seamlessly with your business model. This guide aims to navigate through the key considerations and practical steps to help you make the right choice tailored to your operational needs, ensuring that your investment in automation yields sustainable benefits for years to come.

Understanding Your Business Requirements for Automation Solutions

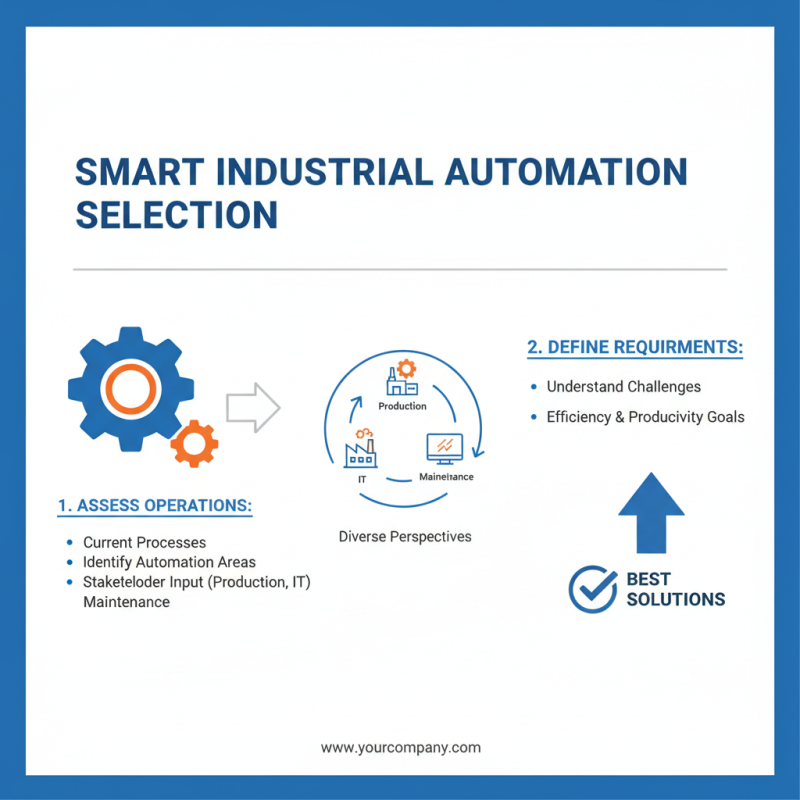

Understanding your business requirements is essential when selecting the best industrial automation solutions. Begin by assessing your current operational processes and identifying areas that could benefit from automation. This evaluation should include input from various stakeholders within the organization, such as production managers, IT staff, and maintenance teams. Gathering insights from these diverse perspectives will help you create a comprehensive understanding of the challenges faced and the opportunities available for improving efficiency and productivity through automation.

Once you have a clear picture of your business needs, prioritize the specific functionalities you seek from automation solutions. Consider factors such as scalability, ease of integration with existing systems, and the technical expertise of your workforce. It's crucial to ensure that the automation system can adapt to your future growth and evolving operational requirements. By carefully defining your objectives, you can more effectively evaluate different automation solutions in the market, ensuring that the chosen technology aligns with your long-term business strategy and delivers a robust return on investment.

Evaluating Different Types of Industrial Automation Technologies

When evaluating different types of industrial automation technologies, it’s crucial to align them with your specific business needs. Start by assessing the scale of your operations and the complexities involved in your production processes. Automation solutions can range from simple programmable logic controllers (PLCs) to advanced robotics and artificial intelligence-driven systems. Understanding your workflow will help narrow down the technologies that can enhance efficiency and productivity.

Tips: Consider conducting a thorough needs analysis by mapping out your current processes and identifying bottlenecks or areas that demand improvement. Engage with stakeholders from various departments to get a comprehensive view of how automation can serve different aspects of your business.

Moreover, explore the scalability of the solutions. As your business grows, your automation needs might evolve. Opting for systems that can easily adapt and expand with your operations will safeguard your investment. Additionally, prioritize technologies that integrate well with your existing systems to minimize disruption during the implementation phase.

Tips: Research industry trends and forecast future needs to stay ahead of technological advancements. Staying informed can enable you to make strategic decisions regarding the types of automation technologies that will be most beneficial now and in the long term.

Industrial Automation Technologies Evaluation

Assessing Vendor Capabilities and Support Services

When choosing industrial automation solutions, assessing vendor capabilities and support services is crucial. Vendors should not only provide robust technology but also demonstrate comprehensive support that matches your operational needs. Look for vendors who have a proven track record in your specific industry. Their experience in similar environments often translates to a better understanding of challenges and more tailored solutions.

**Tip:** When evaluating vendors, inquire about case studies or testimonials from similar businesses. This will give you insight into how well they address specific requirements and challenges faced by companies like yours.

Additionally, consider the level of ongoing support the vendor offers once the solution is implemented. Reliable technical support can be a game-changer in minimizing downtime and ensuring smooth operations. Assess whether support is readily available and if it includes on-site services, online assistance, or dedicated account managers.

**Tip:** Always clarify the SLA (Service Level Agreement) with the vendor to ensure it meets your operational demands and expectations. An understanding of response times and support availability can help you avoid potential headaches in the future.

Comparing Costs and Return on Investment for Automation Projects

When evaluating industrial automation solutions, a critical aspect to consider is the cost versus the return on investment (ROI). The initial costs of automation technology can be significant, encompassing hardware, software, and integration expenses. Businesses must conduct a thorough analysis to estimate both short-term and long-term costs, including ongoing maintenance and potential upgrades. Understanding the total cost of ownership will help companies make informed decisions and budget effectively for their automation projects.

On the return on investment side, businesses should focus on how automation can enhance productivity, reduce labor costs, and improve accuracy in operations. Key performance indicators (KPIs) such as reduced cycle times, increased throughput, and lower error rates can help quantify the benefits of automation. By projecting these metrics against the established costs, companies can construct a compelling ROI analysis that justifies their investment. Furthermore, it's essential to consider the qualitative benefits of automation, such as improved safety and employee satisfaction, which can also significantly impact a business's bottom line over time.

Implementing and Scaling Automation Solutions Effectively

Implementing industrial automation solutions effectively requires a thorough understanding of your business needs and the specific processes you aim to enhance. Begin by assessing the operational bottlenecks and inefficiencies within your current systems. This evaluation will guide you in selecting the right automation technologies that align with your objectives. It’s critical to involve key stakeholders from various departments during this phase to ensure that the selected solutions address the needs across the organization.

Once you have identified suitable automation solutions, focus on a phased implementation strategy. Start with pilot projects that allow you to test the effectiveness of the chosen technology on a smaller scale. This iterative approach helps in fine-tuning processes and provides valuable insights that can inform broader deployment. Furthermore, investing in staff training and change management is essential to facilitate a smooth transition and to maximize the benefits of automation. Engaging employees throughout the process can foster a culture of innovation and adaptability, ensuring that the automation solutions scale effectively across your business.

How to Choose the Best Industrial Automation Solutions for Your Business Needs

| Automation Dimension | Description | Importance Rating (1-5) | Implementation Challenges |

|---|---|---|---|

| Cost Efficiency | Evaluates return on investment and overall cost savings. | 5 | Budget constraints, integration with existing systems. |

| Scalability | Ability to expand capabilities as business grows. | 4 | Potential for future-proofing, technology updates. |

| User-Friendliness | Ease of use for operators and staff training. | 5 | Training time, resistance to change from staff. |

| Integration Capability | How well the automation solution integrates with existing systems. | 4 | Compatibility issues, data migration challenges. |

| Maintenance and Support | Availability of ongoing support and maintenance services. | 3 | Service response times, parts availability. |

Related Posts

-

Exploring Industrial Automation Solutions at the 2025 China Import and Export Fair with Key Industry Insights

-

Exploring Industrial Automation Solutions at the 138th Canton Fair China 2025 Industry Insights

-

Exploring Industrial Automation Solutions at the 138th Canton Fair 2025 Insights and Innovations

-

Top 10 Industrial Automation Solutions Transforming Manufacturing Efficiency

-

Unlocking Growth: Industrial Automation Solutions at China's 138th Canton Fair 2025

-

Revolutionizing Efficiency: How Automation Machines Are Shaping the Future of Manufacturing in 2023