How to Choose the Best Robotic Welding Machine for Your Business Needs

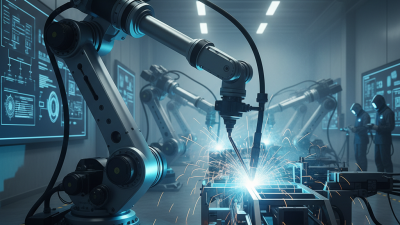

In the rapidly evolving manufacturing landscape, the selection of the right robotic welding machine is pivotal for businesses aiming to enhance productivity and competitiveness. According to Dr. John Smith, a renowned expert in robotic automation, "Choosing the right robotic welding machine can fundamentally transform your production line and streamline operations." This insightful perspective underscores the significance of making an informed decision that aligns with specific business needs and operational goals.

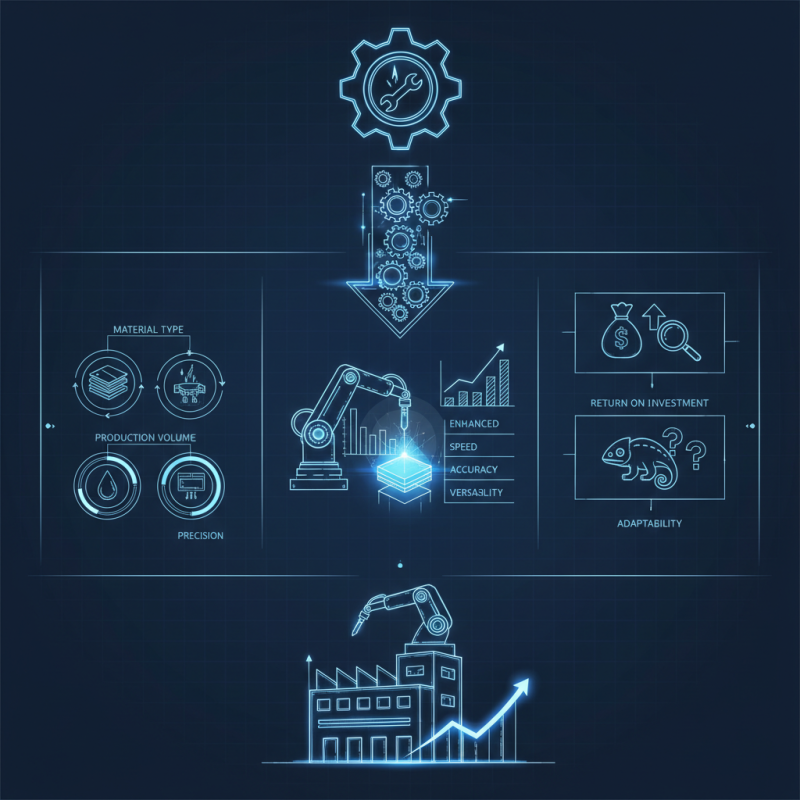

When considering a robotic welding machine, businesses must evaluate several critical factors, including the type of materials to be welded, production volume, and the required precision. With advanced technologies now available, the capabilities of these machines extend far beyond traditional welding methods, offering enhanced speed, accuracy, and versatility. As organizations navigate the complexities of this selection process, they must prioritize not only the technical specifications but also the potential return on investment and the machine's adaptability to future production demands.

In conclusion, investing in the right robotic welding machine is more than just a purchase; it is a strategic decision that shapes the future of manufacturing operations. As industries continue to embrace automation, those who take the time to carefully assess their needs will reap the benefits of increased efficiency and innovation in their welding processes.

Identifying Your Business Welding Requirements and Objectives

When selecting the best robotic welding machine for your business, it’s essential to first identify your specific welding requirements and objectives. Start by assessing the types of materials you typically work with, the thickness of those materials, and the complexity of your welding projects. Understanding these factors will help narrow down your options and ensure that the machine you choose can handle your workload efficiently.

**Tip:** Create a detailed list of your welding tasks and the expected production volume. This will provide clarity on the machine's capabilities you need, such as its speed, precision, and flexibility.

Additionally, consider the scale of your operations. A small workshop may not require the same features as a large manufacturing facility. Evaluate whether you need a machine that is easy to integrate into your existing workflow and can accommodate changes in production. It’s also important to think about future growth—will the machine you choose still meet your needs as your business expands?

**Tip:** Consult with industry experts or conduct tests on a few models to gain insights on how they perform under your specific conditions. This hands-on experience can significantly influence your final decision.

Understanding Different Types of Robotic Welding Machines Available

When selecting a robotic welding machine, it’s essential to understand the different types available on the market to determine which best suits your business needs. The most common types include arc welding robots, spot welding robots, and TIG welding robots. Arc welding robots are ideal for larger components and heavy-duty applications, providing high weld quality with a continuous feed of welding wire. They excel in efficiency and speed, making them suitable for high-volume production environments.

Spot welding robots, on the other hand, are typically used in automotive and manufacturing industries for joining sheet metal components. They offer precision and speed, making them perfect for repetitive tasks. These robots can also handle various materials, which enhances their versatility. Finally, TIG welding robots are known for their ability to produce clean and precise welds, especially in thin materials. This type of robotic welding is often used in industries that require high aesthetic standards, such as aerospace and artistic applications. Understanding these types will help in choosing the right robotic welding solution tailored to specific operational requirements.

Assessing Key Features and Specifications for Welding Machines

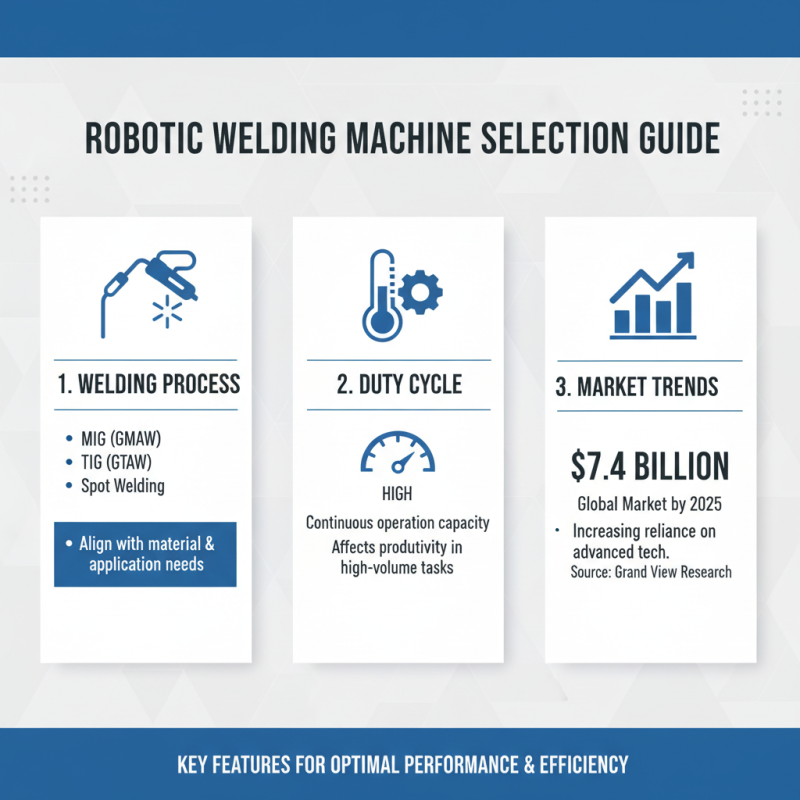

When selecting a robotic welding machine for your business, it's essential to assess key features and specifications that align with your operational needs. One of the primary considerations is the type of welding process the machine supports, such as MIG, TIG, or spot welding. According to a recent industry report by Grand View Research, the global market for robotic welding is expected to reach $7.4 billion by 2025, highlighting the increasing reliance on advanced welding technologies. Evaluating the machine's duty cycle, which indicates how long it can operate continuously without overheating, is also crucial, as it affects productivity and efficiency in high-demand environments.

Another significant aspect to consider is the flexibility and programmability of the welding machine. Modern robotic systems often feature advanced software that allows for easy programming and adjustments, enabling quicker changes between different welding tasks. Research from Markets and Markets suggests that the demand for automated welding processes is driven by the need for precision and quality in manufacturing; hence, a machine with a user-friendly interface and adaptable features can significantly boost operational efficiency. Furthermore, pay attention to safety specifications, including emergency stop functions and safety certifications, to ensure compliance with industry standards while protecting your workforce and equipment.

Evaluating Costs and Return on Investment for Robotic Systems

When evaluating costs and return on investment (ROI) for robotic welding systems, businesses need to consider various factors that directly impact their bottom line. A comprehensive industry report indicates that companies can expect an average ROI of 30% to 50% when investing in advanced robotic welding technology. These figures highlight the potential efficiency gains and productivity improvements that robotic systems can deliver. Additionally, reducing the time spent on manual welding tasks allows firms to allocate their human workforce to more value-added activities, further enhancing overall operations.

Tips for assessing the financial viability of robotic welding machines include conducting a thorough cost-benefit analysis. This analysis should factor in not only the initial investment and maintenance costs but also potential savings on labor and increases in production speed. Furthermore, consider the projected lifespan of the robotic system; many machines can operate effectively for over a decade, which allows for amortized costs that contribute to higher ROI over time.

Additionally, companies should look at metrics like increased weld quality and reduced material waste when measuring the effectiveness of robotic systems. A study by the Fabricators & Manufacturers Association suggests that automating welding processes can reduce defects by up to 90%, leading to significant cost savings on rework and materials. By prioritizing these factors in their evaluation, businesses can make informed decisions that align with their strategic goals and financial performance.

Considerations for Integration and Maintenance of Welding Robots

When considering the integration of robotic welding machines into your operations, the first factor to assess is compatibility with existing systems. Your current setup must be evaluated to determine how well a new welding robot will fit into the workflow. It is essential to ensure that the robotic system can communicate effectively with existing machinery, software, and safety protocols. Conducting a thorough analysis of your production line will facilitate seamless integration, minimizing disruptions during the transition phase.

Maintenance is another critical aspect that must not be overlooked. Regular maintenance schedules for robotic welding systems can significantly extend their lifespan and ensure optimal performance. Establishing a proactive maintenance plan involves routine checks on components such as sensors, cables, and welding tools. Training your team to identify potential issues early on can prevent costly downtime. Additionally, consider the availability of technical support and spare parts, which can impact the efficiency of your maintenance operations. By giving due attention to integration and maintenance, you can maximize the benefits of robotic welding technology in your business.

Related Posts

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

How to Choose the Right Robotic Welding Cells for Your Manufacturing Needs

-

What is Robotic Welding Solutions? Exploring Automation in the Welding Industry with Data Insights

-

How to Improve Your Robotic Welding Techniques for Better Results

-

Top 10 Benefits of Robotic Spot Welding in Modern Manufacturing

-

Exploring Industrial Automation Solutions at the 2025 China Import and Export Fair with Key Industry Insights