How to Choose the Right Robotic Welding Cells for Your Manufacturing Needs

In today's manufacturing landscape, the integration of technology has become a driving force behind efficiency and productivity. Robotic welding cells, as a pivotal innovation, play a significant role in automating welding processes, allowing manufacturers to enhance precision, reduce labor costs, and maintain consistent quality. According to Dr. Emily Chen, a recognized expert in automation and robotics, "Investing in the right robotic welding cells can significantly streamline production while ensuring superior weld integrity." This highlights the necessity for manufacturers to carefully consider their welding cell choices to meet their specific operational needs.

Selecting the appropriate robotic welding cells involves evaluating various factors, including the complexity of the welding tasks, the required speed of production, and the specific materials being used. As the demand for customizable solutions grows, the decision becomes even more critical for manufacturers aiming to stay competitive. By understanding their unique requirements and leveraging the insights of industry experts like Dr. Chen, manufacturers can make informed choices that align with their strategic goals.

Ultimately, the right robotic welding cells can transform production processes, making it essential for companies to undertake thorough research and analysis before implementation. With the continuous evolution of technology, staying abreast of these advancements will empower manufacturers to optimize their welding operations effectively.

Understand Your Manufacturing Requirements for Robotic Welding

When selecting robotic welding cells for manufacturing, it is crucial to first understand your specific manufacturing requirements. According to the International Federation of Robotics, about 80% of industrial robots are utilized in welding applications, underscoring the significance of choosing the right tools for your production line. Assessing variables such as the materials being welded, the complexity of the joints, and the required precision will directly influence your decision. For instance, high-volume production environments may benefit from multi-axis robots that allow for greater flexibility and speed in welding operations.

Moreover, it is essential to evaluate your current operational workflow and identify areas where efficiency can be improved. Research from the American Welding Society indicates that automated welding can improve productivity by over 50% compared to manual welding processes. Understanding the types of welding processes required—such as MIG, TIG, or spot welding—can help narrow down the options to robotic cells designed to handle these specific tasks. Additionally, factors such as integration with existing machinery, the available space in your facility, and potential future expansion plans are crucial elements that should guide the selection process. By tailoring your choice of robotic welding cells to these manufacturing needs, you can enhance productivity, boost quality, and achieve a better return on investment in the long run.

Evaluate Different Types of Robotic Welding Cells Available

When evaluating different types of robotic welding cells, it is crucial to consider various factors that align with your specific manufacturing needs. Robotic welding systems can be broadly categorized into two types: arc welding cells and resistance welding cells. According to market research by Industry Research, the global robotic welding market is expected to reach $6.1 billion by 2027, growing at a compound annual growth rate (CAGR) of 7.9%. This highlights the increasing reliance of manufacturers on automated welding solutions to enhance both productivity and quality.

Arc welding cells, including MIG and TIG welding systems, are often preferred for their versatility and efficiency when working with a variety of materials. These systems are ideal for high-volume production due to their speed and adaptability. On the other hand, resistance welding cells are best suited for joining thin sheets and are particularly effective in the automotive industry, where precision and repeatability are paramount. A report from Research and Markets indicates that automotive applications accounted for over 30% of the robotic welding market share in 2022, emphasizing the importance of selecting the right cell type based on industry-specific requirements and production scales.

Moreover, it's essential to assess additional features such as the cell’s payload capacity, accessibility for maintenance, and integration capabilities with existing machinery. As manufacturers continue to embrace advanced technologies like Industry 4.0, investing in intelligent robotic welding cells that offer real-time data analytics and connectivity can significantly enhance operational efficiency. Tailoring your choice to these parameters not only optimizes production processes but also positions your manufacturing facility to adapt to future technological advancements.

How to Choose the Right Robotic Welding Cells for Your Manufacturing Needs

| Type of Robotic Welding Cell | Key Features | Ideal Applications | Cost Range ($) | Flexibility Level |

|---|---|---|---|---|

| Compact Robotic Cells | Space-saving, Fast installation | Small to medium-sized components, Lightweight materials | 10,000 - 25,000 | High |

| Heavy-Duty Robotic Cells | Sturdy structure, High payload capacity | Heavy industrial applications, Thick materials | 30,000 - 70,000 | Medium |

| Automated Welding Workstations | Integrated with CNCs, High precision | Mass production, High precision tasks | 50,000 - 100,000 | Low |

| Mobile Robotic Cells | Mobility, Adaptive to different tasks | Varied tasks, Flexible environments | 20,000 - 40,000 | High |

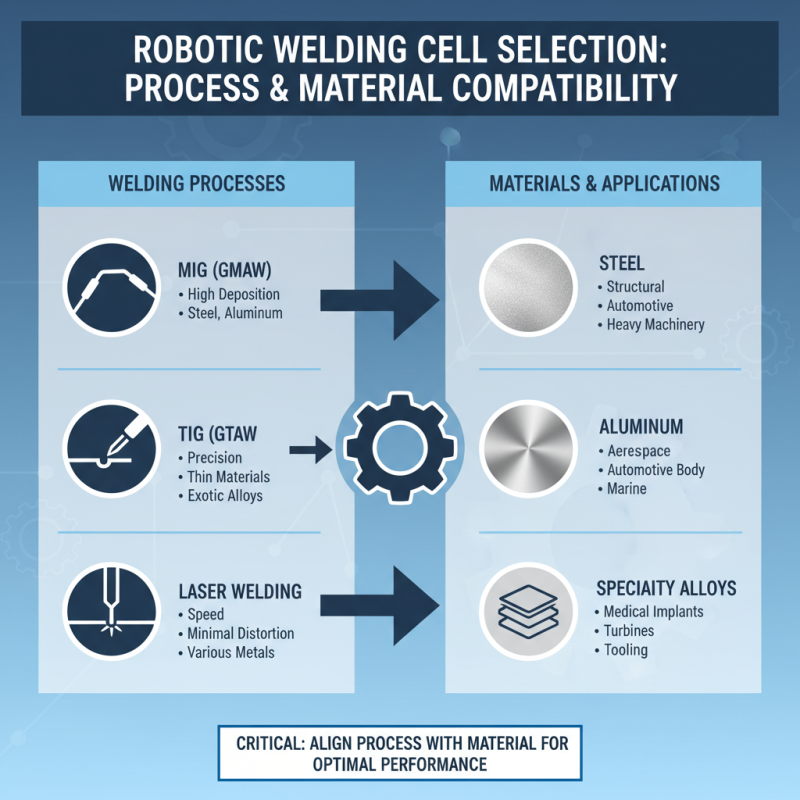

Assess the Compatibility of Welding Processes and Materials

When selecting robotic welding cells, a critical aspect to consider is the compatibility of welding processes and materials used in your manufacturing operations. Different welding methods, such as MIG, TIG, or laser welding, have unique characteristics that make them suitable for specific materials and applications. It's vital to evaluate which welding process aligns best with your production needs and the types of materials being used, whether it's steel, aluminum, or certain alloys.

Additionally, the compatibility of the robotic welding cell with these processes is essential in ensuring optimal performance and weld quality. For instance, the setup of the robotic arm must facilitate the appropriate movements and adjustments for the chosen welding technique. Moreover, it's important to assess the material thickness and the joints to be welded, as this will influence the choice of both the welding process and the robot's configuration. By focusing on these compatibility aspects, manufacturers can enhance production efficiency and achieve superior welding results.

Consider the Space and Layout of Your Manufacturing Facility

When selecting the right robotic welding cells for your manufacturing needs, one crucial aspect to consider is the space and layout of your facility. The dimensions and configuration of your workspace can significantly influence the efficiency and effectiveness of the robotic systems. According to a report from the International Federation of Robotics, approximately 50% of manufacturers report that optimizing their facility layout leads to a decrease in operational inefficiencies. Therefore, a well-thought-out layout not only accommodates the robotic cells but also ensures a streamlined workflow, minimizing material handling and reducing cycle times.

Additionally, the layout should facilitate safe and productive interaction between human operators and robotic systems. Studies have shown that proper spacing can enhance safety and productivity, as it allows for unobstructed movement and quick access to the robotic cells for maintenance or intervention. The Welding Equipment Manufacturers Association notes that a layout designed with ergonomic principles in mind can improve overall workplace satisfaction and reduce worker fatigue. By considering both the physical dimensions of the robotic welding cells and the overall layout of the manufacturing facility, businesses can foster a more efficient and engaging work environment, ultimately leading to increased productivity and profitability.

Robotic Welding Cells Efficiency Comparison

This chart displays the efficiency of various robotic welding cells based on their workspace utilization and production output over a month. The data shows how different layouts and space considerations impact the overall performance of the welding cells.

Analyze ROI and Long-term Maintenance for Robotic Welding Systems

When selecting robotic welding cells for your manufacturing operations, it is essential to analyze the

return on investment (ROI) and the long-term maintenance

required for these systems. Reports indicate that companies can expect an ROI of approximately

20-30% within the first two years of implementing

robotic welding, primarily due to increased efficiency and reduced labor costs. In industries heavily reliant

on precision welding, such as automotive and aerospace, robotic systems can significantly decrease cycle times

while enhancing product quality.

One critical aspect to consider is the ongoing maintenance of robotic welding cells. Industry research highlights

that routine maintenance can reduce unplanned downtimes by up to

50%, ultimately improving overall productivity. Depending on

usage and workload, companies should anticipate maintenance costs to be about

5-10% of the initial investment annually.

Implementing a preventive maintenance schedule can further extend the lifespan of the equipment, ensuring that

the systems continue to operate at optimal levels.

Tips: Regularly assess the capabilities and

performance of your robotic cells to identify areas for potential upgrades or enhancements. Additionally, consider

training your staff on basic maintenance procedures to minimize service interruptions. Engaging with a reliable

service provider for periodic check-ups can also safeguard your investment in robotic welding technology.

Related Posts

-

What is Robotic Welding Solutions? Exploring Automation in the Welding Industry with Data Insights

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency

-

Top 10 Tips for Mastering Robotic Spot Welding Techniques

-

How to Improve Your Robotic Welding Techniques for Better Results