Why Are Industrial Robots Essential for Modern Manufacturing?

In today’s manufacturing landscape, industrial robots play a vital role. Their integration enhances efficiency and precision. According to a report by the International Federation of Robotics, the number of operational industrial robots exceeded 3 million units in 2020. This figure reflects a significant trend in automation.

Experts recognize the importance of these machines. Dr. David L. G. Martin, a well-known robotics specialist, states, “Industrial robots are the backbone of modern production.” His words encapsulate the essential nature of these technologies. Factories employing industrial robots report up to a 30% increase in productivity.

However, reliance on industrial robots raises questions. While they enhance output, they also affect employment. Workers may feel threatened as machines take over tasks. Balancing automation with human roles is crucial. As manufacturing evolves, the conversation about industrial robots must continue. Innovations bring potential but also challenges that need careful consideration.

The Role of Industrial Robots in Enhancing Manufacturing Efficiency

Industrial robots have become crucial in modern manufacturing. They significantly enhance efficiency and productivity. According to a recent study, manufacturers using robotics have seen a productivity increase of up to 30%. This shift is essential for meeting high consumer demands while maintaining quality.

Tasks once done manually can now be automated. Robots handle repetitive tasks with precision, reducing human error. For instance, assembly lines with robots can fulfill orders faster and more accurately. A report from the International Federation of Robotics notes that industrial robot installations have surged by over 15% each year. However, not every company has fully embraced this technology. Some still struggle with integration challenges.

Tip: Consider starting with smaller automation projects. Focus on processes that are labor-intensive or error-prone. This approach allows for gradual adaptation. Embrace the learning curve and refine your strategies.

Companies must also assess their workforce's readiness for automation. Training staff to work alongside robots is vital. Some employees may feel threatened by robots, leading to resistance. Addressing these concerns can foster a smoother transition.

Tip: Engage your team early. Involve them in discussions about technology integration. This can help build trust and acceptance, leading to better outcomes.

Key Benefits of Implementing Industrial Robots in Production Lines

Industrial robots play a pivotal role in modern manufacturing. They automate tasks that are often repetitive and time-consuming. By doing so, they enhance efficiency significantly. This automation reduces human error and increases precision. Workers can focus on higher-level tasks instead. The synergy between human skills and robotic capabilities opens new doors for innovation.

Implementing robots leads to impressive productivity gains. For instance, a production line can operate 24/7, ensuring continuous output. Robots maintain a consistent pace that human workers can struggle to match. However, there can be challenges in integration. Training staff to work alongside robots is essential. Without proper guidance, the transition may cause confusion and slow down operations.

Quality control also benefits from robotic assistance. Robots can inspect products with high accuracy. Yet, there is a risk of over-reliance on technology. If a robot malfunctions, it can halt the entire line. Manufacturers need contingency plans to address these issues. Safety is another concern that needs attention. Ensuring that robots work safely alongside humans is crucial for a harmonious workplace.

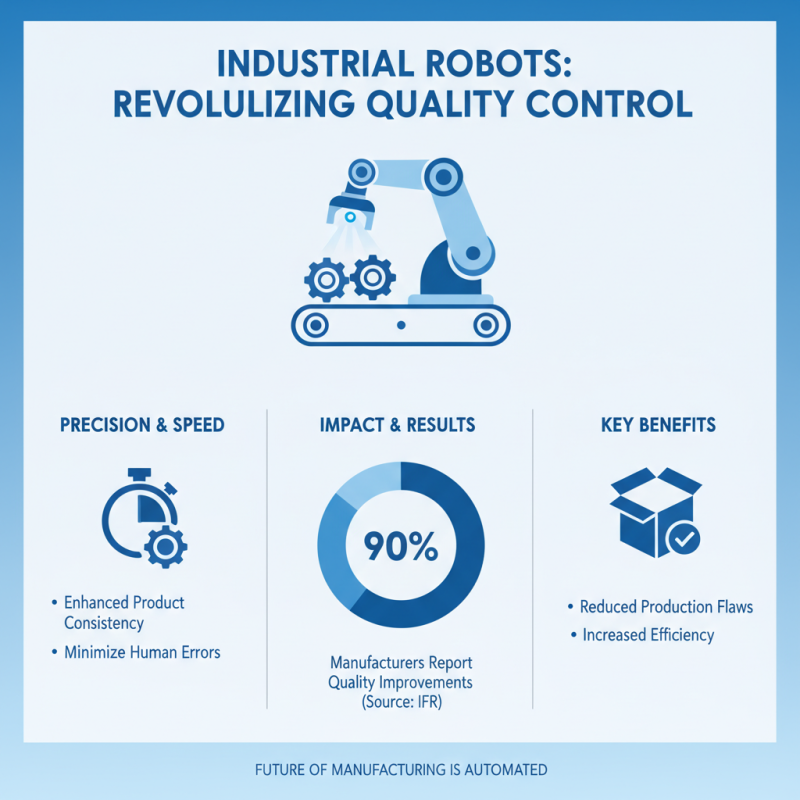

Impact of Industrial Robots on Quality Control and Consistency

Industrial robots are revolutionizing quality control in manufacturing. They enhance product consistency through precision and speed. In a recent study by the International Federation of Robotics, 90% of manufacturers reported significant improvements in quality due to automation. This shift helps minimize human errors, which can lead to flaws in production.

Moreover, robots can perform repetitive tasks with remarkable accuracy. According to a report from McKinsey, companies using robots for quality checks reduced defects by 40%. This reduction not only boosts customer satisfaction but also lowers the costs associated with returns and rework. However, reliance on automation raises concerns. Some argue that overdependence on robots may stifle human oversight. Human intuition can detect anomalies that machines might miss.

Implementing robots does come with challenges. There are upfront costs and a learning curve. Some users report a need for retraining staff to work alongside automation. Balancing technology with human skills is vital for maintaining quality. Effective integration requires ongoing assessment and adjustments.

Challenges and Considerations in Integrating Robots into Manufacturing

Integrating robots into manufacturing presents several challenges. Companies must address workforce retraining as robots take over repetitive tasks. According to a study by the International Federation of Robotics, 40% of workers need new skills to collaborate with machines. This transition can spark resistance. Employees may feel threatened by the technology. Clear communication is essential to ease these concerns.

Another critical consideration is the initial investment in robotics. Research indicates that while robots can increase productivity by up to 300%, the upfront costs can be substantial. A report from McKinsey states that around 40% of companies struggle with budgeting for automation technologies. Companies often underestimate ongoing maintenance expenses. This can lead to unplanned disruptions and delays.

Moreover, there are integration complexities to manage. Each robot must be tailored to fit specific processes. Poorly integrated robots can result in inefficiencies. In fact, the World Economic Forum highlights that 90% of manufacturers experience setbacks during integration. Systems need to communicate seamlessly. Without this, the potential benefits of automation may not be fully realized.

Industrial Robots Adoption in Manufacturing Sectors (2023)

Future Trends in Industrial Robotics and Their Implications for Manufacturing

The future of industrial robotics is rapidly evolving. As technology advances, robots become more capable. They now perform tasks with remarkable precision and speed. This shift is transforming manufacturing processes. Companies are integrating robots for repetitive tasks and complex assembly lines. This efficiency boosts productivity. Yet, it raises questions about the workforce.

Automation could lead to job displacement. Many skilled workers may find their roles changing or disappearing. However, it may also create new opportunities. Training programs will be essential. Upskilling will help workers adapt to new technologies. This transition is not without challenges. The risk of over-reliance on robots is real. A balance between human skills and robotic efficiency is vital.

Emerging trends show a rise in collaborative robots. These robots work alongside humans, enhancing manufacturing capabilities. They are designed to be user-friendly, making them accessible. This fosters innovation and creativity on the shop floor. Yet, reliance on technology must be approached cautiously. It’s essential to reflect on how robots impact the human element in manufacturing. As we advance, the integration of robots should consider ethical implications and workforce dynamics.

Related Posts

-

Top 10 Industrial Robots Transforming Manufacturing in 2023

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Exploring the Future of Automation: How Robot Machines are Revolutionizing Industry Efficiency

-

Revolutionizing Efficiency: How Automation Machines Are Shaping the Future of Manufacturing in 2023

-

Unlocking the Future: How FANUC Robots are Transforming Industries One Task at a Time