10 Essential Tips for Implementing Robotic Automation Effectively?

In today's fast-paced industrial environment, robotic automation plays a crucial role in enhancing productivity. Implementing robotic automation effectively can be a daunting challenge. Companies often rush into adopting robots without thoroughly understanding their needs or potential impacts. This haste may lead to unexpected costs and inefficiencies.

A well-planned approach is essential. Focus should be on specific tasks that robots can perform better than humans. It is vital to assess workflows and identify bottlenecks that automation can address directly. Some companies overlook the importance of training staff to work alongside robots. This oversight can create friction and hinder overall performance.

Every business is unique, and so are its robotic automation needs. What works for one might not work for another. Therefore, a flexible mindset is necessary. Regular evaluation of robotic systems is needed, as performance may not meet initial expectations. Staying adaptable can lead to continuous improvement and greater success in implementing robotic automation.

Identifying Key Processes for Robotic Automation Implementation

Identifying the right processes for robotic automation can be challenging. Start by analyzing repetitive tasks. Look for processes that require minimal human judgment and are rule-based. These tasks are often ripe for automation. You may find manual data entry or invoice processing beneficial for robots. Both tasks are labor-intensive and time-consuming.

Consider the complexity of the processes. If a task has numerous exceptions, it may not be suitable for automation. For example, processing customer inquiries often varies greatly. It requires human empathy and situational awareness. This type of work can lead to misunderstandings and errors when automated.

Test the boundaries before fully committing to any process. Assess scalability and impact too. Can the automated process grow with your business? Remember, automation should enhance efficiency, not overwhelm your team.

Monitor the performance regularly. It will provide insights into the success of your implementation. You may uncover unexpected drawbacks along the way. Evaluating and adjusting will improve your robotic automation journey.

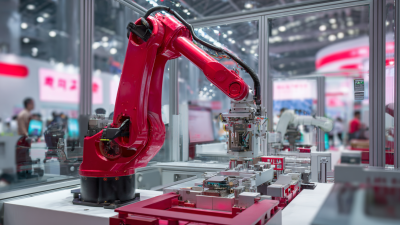

Assessing the Right Technology and Tools for Automation

When it comes to robotic automation, selecting the right technology is crucial. Organizations must evaluate their specific needs before diving into tools. Assessing current workflows helps identify bottlenecks and areas for improvement. It's not always about adopting the latest technology. Sometimes, the simplest solutions work best.

Different tasks require different automation tools. A thorough analysis can reveal gaps in capabilities. Teams should consider the flexibility and scalability of technology. What works today may not fit future demands. This ongoing evaluation process is essential. It prevents businesses from getting locked into ineffective solutions.

Not every automation tool shines under scrutiny. Some might look promising but fall short in real-world applications. Regular feedback loops with employees can uncover these issues. They often have firsthand experience with technology's strengths and weaknesses. Listening to their insights can help refine the automation strategy over time.

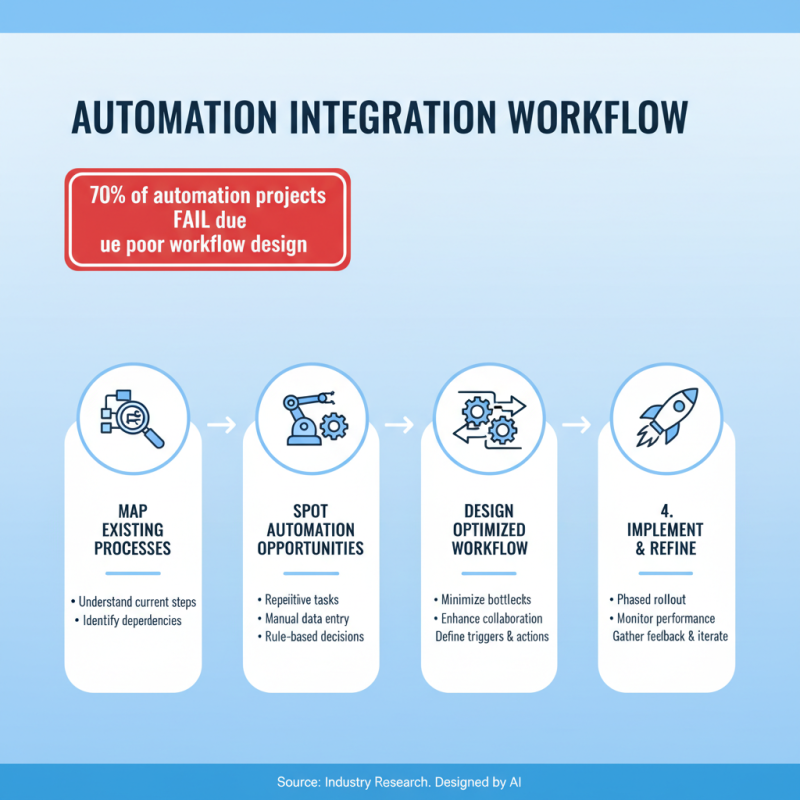

Designing an Effective Workflow for Automation Integration

Designing an effective workflow for automation integration requires a clear understanding of both process and technology. Research shows that 70% of automation projects fail due to poor workflow design. A well-structured workflow minimizes potential bottlenecks. It also enhances collaboration among team members. Begin by mapping out existing processes. Identify repetitive tasks ripe for automation.

Next, ensure that the technology aligns with your workflow. Data from McKinsey suggests that organizations that tailor their tech to fit workflows improve efficiency by 60%. However, it’s important to remain flexible. As automation progresses, workflows may need adjustments. Build feedback loops to maintain relevance over time. Encourage team members to voice concerns or suggest improvements.

Tracking performance metrics is crucial. Use key performance indicators (KPIs) to monitor the effectiveness of the automated workflow. Be ready to pivot. Some automation strategies may not yield the expected results. Continuous evaluation and adaptation are essential for long-term success. Automation should enhance, not hinder, the work process.

Training Employees for Successful Adoption of Robotic Automation

Training employees for robotic automation is crucial. Organizations must prioritize effective training programs. Start with understanding employee concerns about automation. Many may fear job loss or feel intimidated by new technology. Address these fears openly to ease tensions.

Hands-on training is essential. Allow employees to interact with robotic systems in a safe environment. Create small groups for peer learning. Provide real scenarios for practice. This builds confidence and reduces anxiety. Remember, not everyone will grasp concepts at the same pace. Be patient and provide additional resources for those who need them.

Feedback is vital. After training sessions, gather input from participants. Understand what worked and what didn't. Some may find certain aspects confusing or overwhelming. This can guide future improvements. Keep communication channels open. Regularly check in with employees to assess their comfort level with robotic processes. This ongoing support fosters a culture of adaptability.

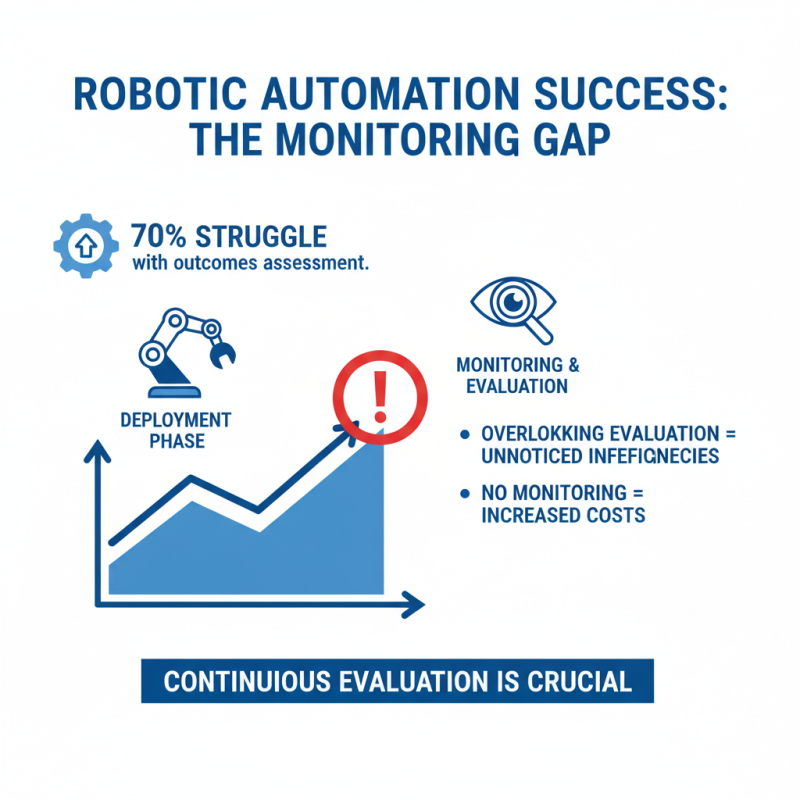

Monitoring and Evaluating Automation Performance and Effectiveness

Monitoring and evaluating the performance of robotic automation is crucial for success. According to a recent industry report, 70% of organizations struggle with effectively assessing automation outcomes. Many companies overlook this phase. They focus solely on deployment, ignoring the importance of continuous evaluation. Without proper monitoring, inefficiencies might go unnoticed, leading to increased costs.

To ensure effectiveness, establish clear KPIs. For example, time saved and error rates are common metrics. However, tracking is not enough. Regularly review the data with your team. Assess trends and identify areas where automation may not be meeting your expectations. A study found that organizations that actively engage in performance evaluations see 30% higher satisfaction in their automation initiatives.

Another concern involves the integration of human oversight. While robots can handle repetitive tasks, employees' feedback is invaluable. Their insights can highlight process shortcomings that numbers alone cannot reveal. Aim for a balanced approach. Rely on data, but don’t ignore human perspective. Automation is a tool, but it should complement human effort, not replace it. Regular reflection on both human and automated inputs is essential for sustainable success.

Related Posts

-

Why Automation Industry is Key to Future Business Success

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Exploring the Future of Robotic Manufacturing at China's 138th Canton Fair 2025

-

Exploring the Future: How Robotic Automation is Revolutionizing Everyday Tasks and Industries

-

Innovative Robotic Solutions Transforming Industries for a Sustainable Future