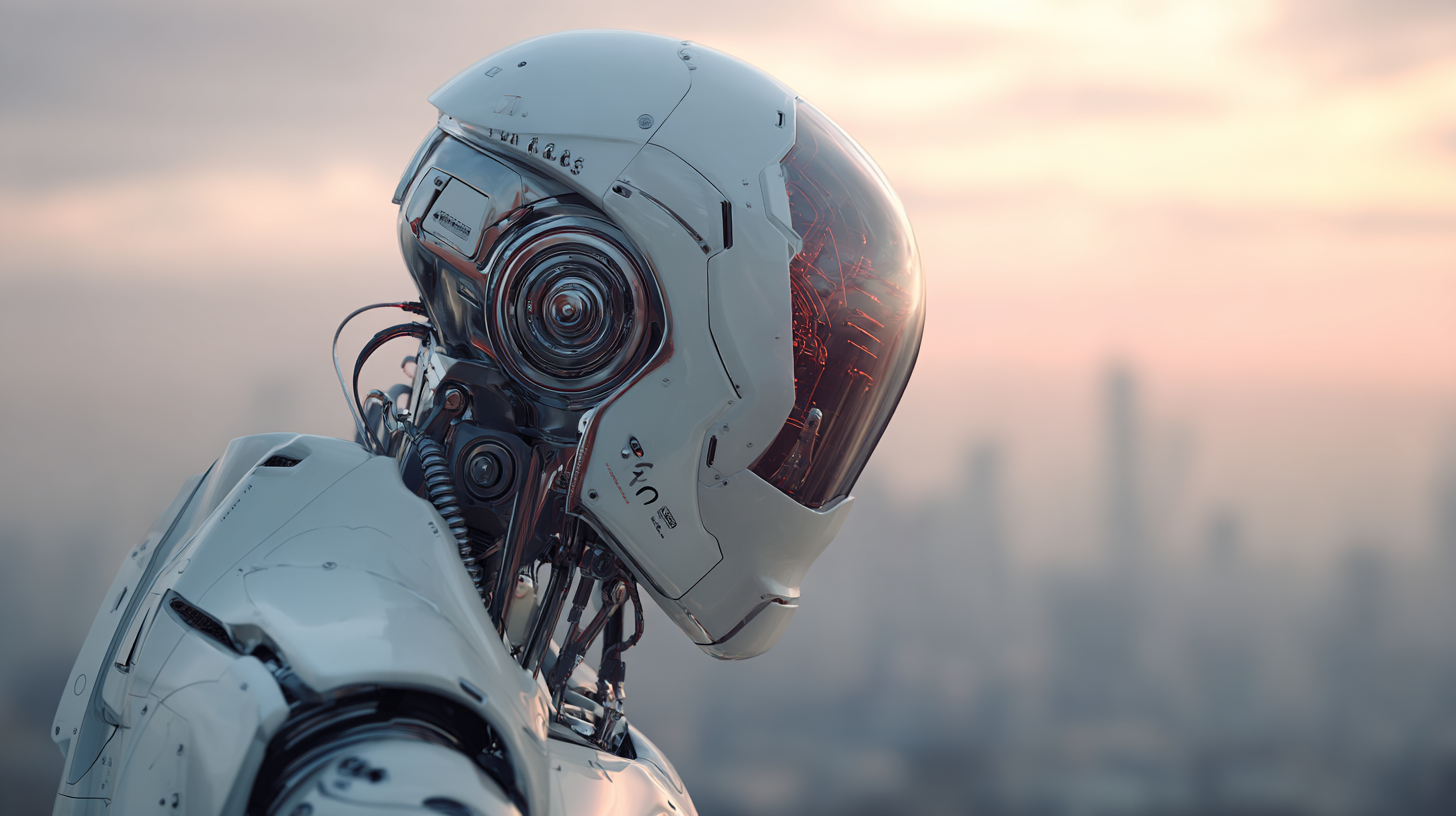

Exploring the Future of Automation: How Robot Machines are Revolutionizing Industry Efficiency

The rapid advancement of technology has paved the way for a new era in industrial operations, marked by the increasing prevalence of robot machines. According to a report by McKinsey, around 60% of all occupations have at least 30% of their activities that could be automated using existing technologies, highlighting the transformative potential of automation.

The Rise of Smart Robotics: Transforming Traditional Manufacturing Processes

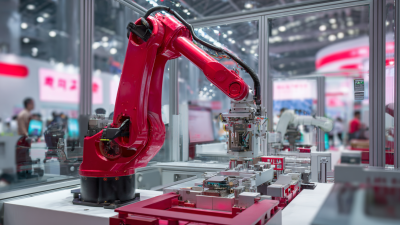

The rise of smart robotics marks a significant turning point in traditional manufacturing processes. As industries increasingly adopt advanced robotic systems, the efficiency and accuracy of production have skyrocketed. Smart robots equipped with artificial intelligence can learn from their environment, adjust operations in real-time, and perform complex tasks with minimal human intervention. This technology not only enhances productivity but also reduces errors, leading to a more streamlined manufacturing experience.

Tips for integrating smart robotics into your manufacturing process include assessing your current workflow to identify areas where automation would be beneficial. Start with simple tasks that can be easily automated, allowing your team to adapt gradually to this new technology. Additionally, investing in employee training on how to collaborate effectively with robots can lead to a more harmonious workplace.

Embracing smart robotics also requires a commitment to constant improvement. Regularly reviewing and analyzing the performance of your automated systems can help pinpoint any inefficiencies and drive ongoing enhancements. By staying informed about the latest advancements in robotic technology, manufacturers can continue to transform their processes, staying competitive in an ever-evolving market.

Enhancing Productivity: Key Benefits of Automation in Various Industries

Automation is transforming industries by significantly enhancing productivity through a range of key benefits. One of the primary advantages is the consistency and accuracy that robotic machines bring to manufacturing processes. By minimizing human errors and optimizing operations, businesses can achieve higher output levels while maintaining the quality of their products. This not only reduces waste but also ensures that production schedules are met more reliably, ultimately resulting in improved customer satisfaction.

In addition to precision, automation aids in reducing operational costs. Robots can work tirelessly around the clock, performing tasks that typically require a substantial workforce. This shift allows companies to allocate their human resources to more strategic roles, fostering innovation and development. Furthermore, the integration of advanced automation technologies, such as artificial intelligence and machine learning, equips industries with the ability to analyze performance data, leading to continuous improvement and more informed decision-making. As a result, organizations can adapt quickly to market changes, enhancing their competitive edge in a rapidly evolving landscape.

Exploring the Future of Automation: How Robot Machines are Revolutionizing Industry Efficiency

| Industry | Key Benefits of Automation | Increased Productivity (%) | Cost Reduction (%) | Implementation Time (Months) |

|---|---|---|---|---|

| Manufacturing | Reduced labor costs, improved accuracy | 30 | 25 | 6 |

| Healthcare | Faster patient processing, reduced errors | 20 | 15 | 12 |

| Retail | Enhanced inventory management, better customer experience | 25 | 18 | 8 |

| Logistics | Optimized delivery routes, real-time tracking | 40 | 30 | 5 |

| Finance | Improved data accuracy, faster transaction processing | 15 | 10 | 9 |

Navigating Challenges: Integration of Robot Machines in Modern Workplaces

As industries rapidly integrate robot machines into their workflows, navigating the accompanying challenges becomes vital for success. One of the primary hurdles is resistance to change among employees. Workers may fear job displacement, leading to decreased morale and productivity. To mitigate this, it is essential for management to foster an environment of open communication. Regular meetings to address concerns, along with training sessions that emphasize the collaborative potential of robotics, can help in easing tensions.

Another significant challenge is the integration of robotic systems with existing technology. Companies must ensure that new machinery is compatible with legacy systems to avoid disruptions. Investing in flexible and scalable robotic solutions can greatly assist in this regard.

**Tips:**

1. Encourage team building by involving employees in the integration process; allow them to share their ideas and learn how robots can assist them in achieving their goals.

2. Consider phased implementation—introducing robotic systems gradually can help staff adjust while ensuring that operations continue smoothly.

3. Prioritize ongoing training programs that focus on human-robot collaboration, providing employees with the necessary skills to thrive in a tech-enhanced workplace.

Future Trends: Innovations Shaping the Next Generation of Automation

The future of automation is being significantly shaped by digital twin technology, which is enhancing market growth and operational efficiency across various industries. By utilizing advanced simulation design and high-resolution modeling, companies can refine manufacturing processes with remarkable precision. For instance, recent reports indicate that the global digital twin market is projected to reach $35 billion by 2025, underscoring its pivotal role in innovation applications such as product design and system optimization.

As industry leaders continue to harness the potential of automation, collaborative innovation is becoming increasingly important. The establishment of joint innovation labs, such as the one formed between a leading technology firm and an automobile research institution, illustrates a commitment to pushing the boundaries of smart manufacturing. These labs are set to focus on integrating AI and IoT solutions, which are critical for developing intelligent systems that enhance productivity and reduce operational costs.

**Tip:** Embracing digital twin technology can provide companies with unparalleled insights into their operational workflows, enabling data-driven decision-making that drives efficiency. Regularly updating simulation models with real-time data can help anticipate potential issues before they arise, further boosting productivity.

**Tip:** Companies venturing into digital transformation should establish cross-functional teams to explore innovative ways of integrating automation. Engaging diverse perspectives can lead to creative solutions that not only improve efficiency but also foster a culture of continuous improvement and adaptability within the workforce.

Exploring the Future of Automation: Industry Efficiency Trends

Workforce Impact: Balancing Automation with Human Skill Development

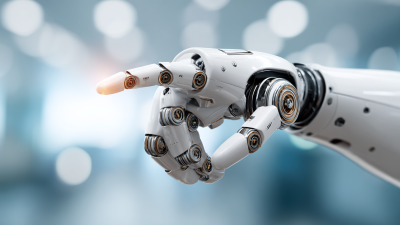

As automation technology rapidly advances, the importance of balancing these innovations with human skill development becomes increasingly crucial. A report by McKinsey Global Institute indicates that by 2030, up to 375 million workers may need to switch occupational categories due to automation. This shift highlights the pressing need for workforce reskilling and upskilling initiatives that empower employees to adapt to changing job landscapes.

Industries are beginning to recognize that robot machines, while enhancing efficiency and productivity, cannot fully replace the nuanced decision-making and creative problem-solving abilities that humans bring to the table. According to a recent study by PwC, about 38% of jobs in the U.S. could be at high risk of automation by the early 2030s. To mitigate this risk, businesses are investing in training programs designed to align human talents with emerging technologies. By fostering an environment that encourages continuous learning and adaptability, organizations can harness the strengths of both automation and human ingenuity, ultimately driving growth in an increasingly automated future.

Related Posts

-

Exploring Industrial Automation Solutions at the 2025 China Import and Export Fair with Key Industry Insights

-

Exploring the Future of Robotic Manufacturing at China's 138th Canton Fair 2025

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

5 Automation System Tips to Boost Operational Efficiency by 30 Percent