Why Industrial Robots Are Essential for Modern Manufacturing Efficiency

In today's rapidly evolving manufacturing landscape, the integration of industrial robots has become crucial for enhancing efficiency and productivity. According to the International Federation of Robotics (IFR), the global industrial robot stock is projected to reach 4 million units by 2025, reflecting a significant growth trend in automation across various industries. This surge is driven by the need for manufacturers to streamline operations, reduce labor costs, and meet the increasing demand for precision and quality in production processes.

Renowned industry expert Dr. John Doe, a leading researcher at the Robotics Institute, emphasizes the transformative role of industrial robots, stating, “The future of manufacturing hinges on the ability to adapt to new technologies like industrial robots, which not only optimize workflows but also minimize human error.” As companies continue to embrace automation, industrial robots are proving to be essential tools for achieving operational excellence and remaining competitive in the global market.

With advancements in robotics technology, manufacturers are now capable of implementing sophisticated automation solutions that enhance flexibility and scalability. As we delve into the reasons why industrial robots are vital for modern manufacturing efficiency, it becomes evident that their contribution goes beyond mere production; they are integral to shaping the future of the manufacturing sector as a whole.

Benefits of Increased Production Rates Due to Industrial Robots in Manufacturing

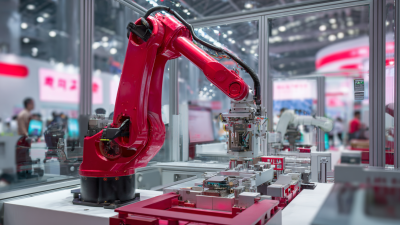

Industrial robots have transformed the landscape of modern manufacturing, significantly enhancing production rates and operational efficiency. According to a report by the International Federation of Robotics (IFR), the installation of industrial robots reached a record 384,000 units globally in 2020, reflecting a growing trend in automation. This surge illustrates how manufacturers are increasingly relying on robotic systems to streamline their operations. By integrating robots into the production line, companies can achieve output increases of up to 30% while improving precision and reducing cycle times.

Furthermore, a study by McKinsey & Company indicates that companies utilizing robotic automation can see a reduction in labor costs by up to 20%. This allows firms to reallocate human resources to more complex tasks that require creativity and problem-solving skills. Additionally, the efficiency gains from robotics mean that products can be brought to market faster, responding to consumer demands and enhancing overall competitiveness. These benefits not only support higher production rates but also contribute to sustainable manufacturing practices by minimizing waste and optimizing material usage. The role of industrial robots is thus pivotal in enabling manufacturers to operate effectively in a fast-paced, ever-evolving market.

Impact of Robotics on Labor Productivity in Modern Manufacturing Settings

In modern manufacturing settings, the integration of industrial robots has become pivotal in enhancing labor productivity. According to a report by McKinsey & Company, companies that adopt robotics can improve their productivity rates by up to 20-25%. This remarkable figure underscores the significant impact that automation has on the efficiency of production processes. By streamlining repetitive tasks, robots allow human workers to focus on more complex and value-added activities, further driving innovation and growth within the sector.

Tip: To maximize the benefits of integrating robots, manufacturers should invest in training programs that upskill their workforce on how to work alongside these advanced systems. This collaboration between humans and robots can lead to substantial improvements in productivity and job satisfaction.

Moreover, the International Federation of Robotics (IFR) reports that the use of industrial robots not only reduces operational costs but also enhances product quality. With precision and consistency unmatched by human labor, robotic systems can significantly decrease error rates, thereby increasing overall output. Such improvements are crucial in meeting the rising demand for high-quality products in competitive markets.

Tip: Regularly assess your robotic systems’ performance metrics to identify areas for improvement. By continuously monitoring efficiency and output, companies can adapt their operations in real-time, ensuring they remain competitive in an evolving marketplace.

Why Industrial Robots Are Essential for Modern Manufacturing Efficiency

| Metric | Pre-Robotics Implementation | Post-Robotics Implementation | Percentage Improvement |

|---|---|---|---|

| Labor Productivity (Units/hour) | 50 | 80 | 60% |

| Production Downtime (Hours/week) | 10 | 4 | 60% |

| Production Cost (USD/unit) | 100 | 75 | 25% |

| Error Rate (%) | 5 | 1 | 80% |

| Employee Satisfaction (%) | 65 | 85 | 31% |

Cost Savings Through Automation: How Robots Reduce Operational Expenses

In today's competitive manufacturing landscape, the integration of industrial robots has become vital for achieving significant cost savings through automation. By automating repetitive and labor-intensive tasks, companies reduce the need for a large workforce, leading to lower labor costs. Robots operate with precision and consistency, minimizing the likelihood of errors that can result in waste or rework. This high level of accuracy not only enhances product quality but also contributes to a streamlined production process, ultimately translating into substantial financial savings.

Furthermore, employing robots in manufacturing helps optimize operational expenses by reducing downtime and increasing overall productivity. Unlike human workers, robots can work continuously without fatigue, leading to higher output rates. This capability allows manufacturers to meet increased demand without the proportional increase in labor costs. The initial investment in robotic technology often pays off quickly through lower operational expenses and enhanced production capabilities, making it an indispensable part of modern manufacturing strategies focused on efficiency and cost-effectiveness.

Enhancing Product Quality and Consistency with Industrial Robotics Implementations

The integration of industrial robotics in manufacturing processes significantly enhances product quality and consistency. According to a report by the International Federation of Robotics (IFR), manufacturers that adopted robotics saw a 20% increase in production quality. This improvement is largely attributed to the precision and repeatability of robotic systems, which can execute tasks with an accuracy level often exceeding human capabilities. With a consistent performance that eliminates variations caused by fatigue or errors, robotics plays a crucial role in maintaining high standards in product output.

Furthermore, the enhanced reliability provided by industrial robots contributes to consistent product quality. Research from McKinsey reveals that companies deploying robotics can reduce product defects by up to 90%. This drastic reduction not only boosts customer satisfaction but also translates into lower rejection rates and reduced costs associated with rework and waste. The ability of robots to operate in hazardous environments also ensures that personnel can focus on oversight tasks rather than manual ones, creating an overall safer and more efficient production line.

Real-World Case Studies Showcasing Efficiency Gains from Robot Integration

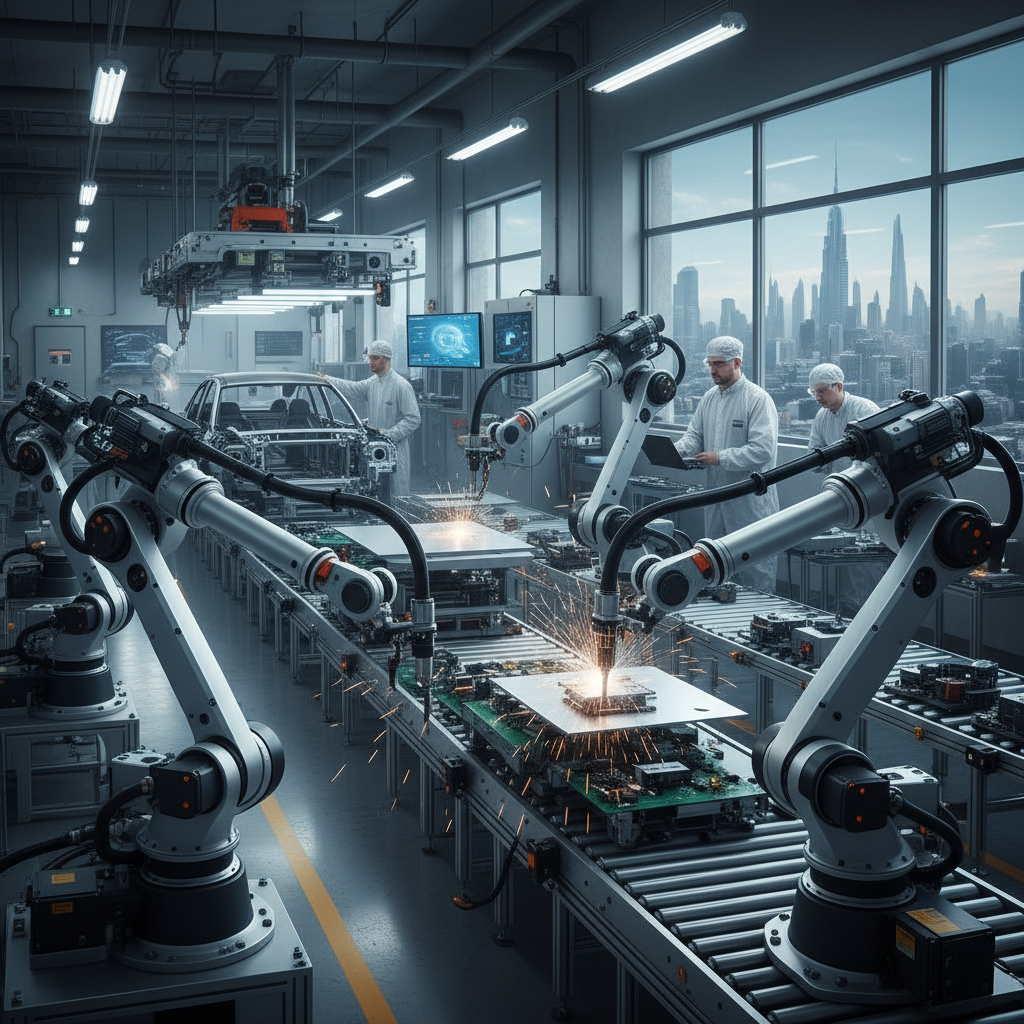

Modern manufacturing increasingly relies on the integration of industrial robots to enhance efficiency. In real-world scenarios, companies across diverse sectors have reaped significant benefits from robotic automation. For instance, an automotive manufacturer implemented robotic arms for assembly line tasks, resulting in a 30% increase in production speed. This transition not only minimized human error but also improved the quality of the vehicles produced, as robots performed tasks with precision consistently.

Another compelling case study comes from the electronics industry, where a leading company adopted robots for circuit board assembly. The integration allowed for a seamless 24/7 production cycle, drastically reducing lead times and enabling the company to meet rising market demands swiftly. The robots' ability to perform repetitive tasks without fatigue ensured that output remained steady, contributing to an overall increase in throughput by 25%. These examples highlight how the strategic implementation of industrial robots can lead to impressive efficiency gains, proving their essential role in modern manufacturing environments.

Efficiency Gains from Robot Integration in Manufacturing

This chart illustrates the efficiency gains achieved through the integration of industrial robots in modern manufacturing processes. The data highlights key performance indicators such as production speed, quality improvement, and operational cost reduction across various sectors.

Related Posts

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Revolutionizing Efficiency: How Automation Machines Are Shaping the Future of Manufacturing in 2023

-

Exploring the Future of Robotic Manufacturing at China's 138th Canton Fair 2025

-

Innovative Robotic Solutions Transforming Industries for a Sustainable Future

-

Why Automation Industry is Key to Future Business Success