How to Master Robotic Spot Welding: Techniques and Best Practices

Robotic spot welding has transformed the manufacturing landscape. This technique plays a vital role in various industries, from automotive to electronics. Mastering robotic spot welding requires an understanding of its fundamental principles and the nuances of execution.

Effective robotic spot welding involves precision and consistency. You need to set up the machinery correctly. Adjust the settings based on the materials being joined. The goal is to achieve a strong bond without damaging the components. However, this process can be challenging. Occasionally, weld quality may vary. This inconsistency invites reflection and adjustment.

Additionally, understanding the robot's movements and capabilities is crucial. Knowledge of programming and maintenance can enhance performance. Regularly reviewing results allows for continuous improvement. Embracing both successes and mistakes in robotic spot welding can lead to mastery. In the world of automation, every detail counts.

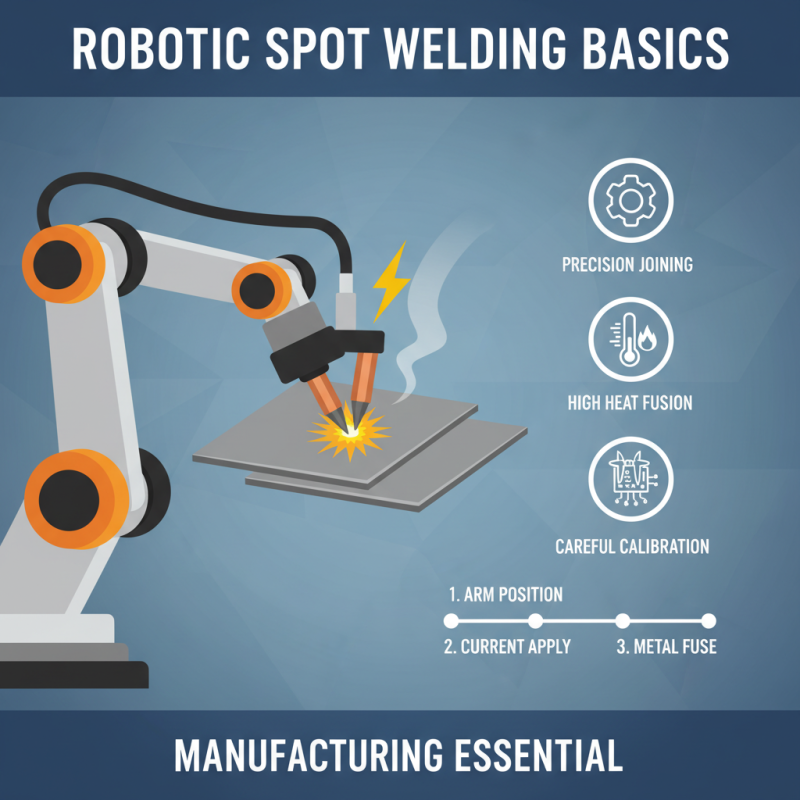

Understanding the Basics of Robotic Spot Welding

Robotic spot welding is a crucial process in manufacturing. It uses high heat to join metal pieces together. Understanding its basics is key for successful implementation. The process involves using a welding gun that applies current through metal parts. When metal pieces fuse, molten pools are formed. This technique is precise but requires careful calibration.

Setting parameters like electrode pressure and welding duration is essential. Incorrect settings can lead to weak joints. Sometimes, welds can appear strong but may contain hidden flaws. Regular inspection of weld quality is also important. Even experienced operators can miss issues.

Moreover, training is vital. Operators need to understand the machine and the materials. They should be aware of common pitfalls, such as overheating. Experimenting with different techniques can yield better results. Mastery comes with practice and continuous learning from mistakes. Every detail matters in achieving a reliable weld.

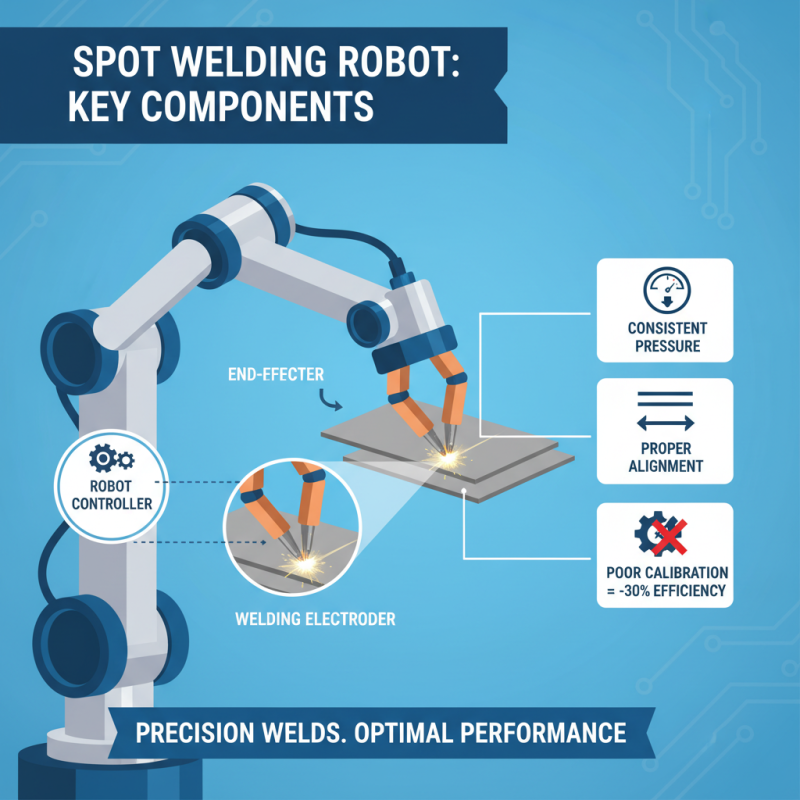

Key Components and Their Functions in Spot Welding Robots

Spot welding robots are complex machines, relying on key components to execute precise welds. The robot's end-effector is crucial. It holds the welding electrodes, ensuring they maintain consistent pressure. Proper alignment is vital. Misalignment can lead to weak welds or even equipment damage. Research shows that poorly calibrated systems can reduce efficiency by up to 30%.

Next, the power supply is another essential component. It provides the energy needed for the welding process. Effective power management ensures consistent weld quality. According to industry standards, fluctuations in power can create inconsistent welds. This inconsistency can erode product quality and lead to higher rejection rates.

Finally, the control system oversees the welding parameters. It adjusts the timing and force applied during the process. However, the complexity of programming can lead to errors. Incorrect settings might cause burn-through or insufficient fusion. Reflection on these challenges is important. Understanding each component's role is essential. Continuous learning can improve performance in robotic spot welding.

Essential Techniques for Effective Spot Welding

Spot welding is a crucial process in various industries, especially automotive manufacturing. Effective techniques for spot welding significantly influence product strength and integrity. According to a report by the International Journal of Advanced Manufacturing Technology, improper settings can lead to a 20% reduction in weld strength. Hence, understanding the essential techniques is vital.

One of the fundamental techniques is controlling the welding parameters. Both time and current must be precisely managed. A recent study indicated that setting the welding current too high can cause burn-through in thin materials. This could lead to a weaker joint and might necessitate rework. It’s crucial to balance these parameters.

Robot programming skills play a critical role, too. Inaccurate tool path can create inconsistent weld quality. As reported in robotic welding analysis, a mere 5% inaccuracy can cause a 15% drop in production efficiency. Regular maintenance checks and calibration can mitigate such issues. Regular audits help identify areas needing improvement. The practice itself is a continual learning process that requires adaptation and refinement over time.

How to Master Robotic Spot Welding: Techniques and Best Practices - Essential Techniques for Effective Spot Welding

| Technique | Description | Best Practice | Common Issues |

|---|---|---|---|

| Electrode Selection | Choosing the right electrode material for welding different metals. | Use copper alloys for general purposes, and ensure correct tip geometry. | Inconsistent welds due to incorrect electrode material. |

| Welding Parameters | Setting optimal current, voltage, and time for spot welding. | Run parameter tests to find the ideal settings for materials. | Overheating or underheating the welds. |

| Joint Design | Designing joints that allow for effective heat transfer and strength. | Utilize lap joints for better accessibility and strength. | Weak joint strength due to poor design. |

| Robot Programming | Programming the robot for precise movement and timing. | Use efficient paths to minimize cycle time. | Misalignment of welds due to poor programming. |

| Maintenance | Regular checks and maintenance of equipment and tooling. | Implement a routine maintenance schedule and inspection protocol. | Equipment failures leading to production downtime. |

Common Challenges and Solutions in Robotic Spot Welding

Robotic spot welding can elevate manufacturing efficiency but faces several challenges. One common issue is inconsistent weld quality. According to a 2022 industry report, nearly 30% of welds can fail inspection due to poor execution. This inconsistency often arises from poor alignment or improper electrode settings.

Tips: Regularly calibrate your robots to ensure precision. Small adjustments can significantly improve weld integrity.

Another challenge is equipment maintenance. Ignoring routine checks can lead to malfunctions. A survey showed that 40% of robotic welding issues stem from neglecting maintenance. Operators must monitor wear and tear. Additionally, programming errors can be a significant hurdle. Data suggests that up to 20% of downtime is due to programming mistakes.

Tips: Implement a systematic training program for operators. Knowledge gaps can cause delays and increase costs.

Addressing these issues requires proactive measures. Investing in training and maintenance can lead to better performance. While challenges remain, continuous improvement can lead to a robust welding process. This is essential for staying competitive in the market.

Common Challenges in Robotic Spot Welding and Their Solutions

Best Practices for Maintenance and Safety in Spot Welding Operations

In robotic spot welding, maintaining equipment is crucial. A well-maintained robot ensures consistent performance. Regularly check the welding guns and electrodes. Wear and tear can lead to defects. Minor adjustments can make a significant difference in quality.

Safety should be a priority. Always wear protective gear. This includes gloves, helmets, and safety glasses. Ensure your work area is free of hazards. Tools should be organized to prevent accidents. Emergency shut-off switches should be easily accessible.

Training for operators is essential. Even small mistakes can lead to costly errors. Encourage team members to report issues immediately. Foster an environment where they feel comfortable discussing concerns. Reflect on past mistakes to improve processes. Continuous improvement is key in achieving excellence in spot welding.

Related Posts

-

How to Choose the Right Robotic Welding Cells for Your Manufacturing Needs

-

What is Robotic Welding Solutions? Exploring Automation in the Welding Industry with Data Insights

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency