Top 10 Robotic Systems Revolutionizing Industries in 2023

In an era marked by rapid technological advancements, robotic systems are at the forefront of industrial innovation. As industries continuously strive for efficiency and productivity, the integration of robotics has become paramount. According to Dr. Emma Chen, a leading expert in robotic systems, "The evolution of robotic systems is unlocking new potentials across various sectors, enabling businesses to operate with unprecedented accuracy and speed." This assertion underscores the transformative impact that robotics are having in fields such as manufacturing, logistics, healthcare, and agriculture.

As we delve into the top 10 robotic systems that are revolutionizing industries in 2023, it becomes evident that these advanced technologies not only enhance operational capabilities but also redefine the roles of human workers. The collaborative synergy between humans and robotic systems is paving the way for more innovative workflows and increased safety in hazardous environments. By exploring these groundbreaking systems, we can gain insights into how they are reshaping the landscape of industries and driving economic growth in an increasingly automated world.

Top 10 Robotic Systems Transforming Manufacturing Processes in 2023

The manufacturing sector is undergoing a significant transformation, driven by innovative robotic systems that enhance efficiency and precision. In 2023, a new wave of robotics is optimizing production lines, from autonomous mobile robots (AMRs) to collaborative robots (cobots), which work alongside human workers to improve workflows. These systems not only reduce labor costs but also minimize errors and downtime, ensuring that manufacturing processes are streamlined and highly productive.

Tips for manufacturers looking to adopt robotic systems include assessing the specific needs of their operations. It’s crucial to identify areas where automation can provide the most value, whether through increasing output, improving safety, or enhancing quality control. Furthermore, investing in employee training can maximize the benefits of integrating robotic technologies, ensuring that staff are equipped to work effectively alongside machines.

Another important aspect is the scalability of robotic systems. Manufacturers should consider solutions that can evolve with their operations, allowing for modifications without extensive overhauls. This flexibility can help businesses adapt to market changes and demands quickly. By planning for future growth, companies can ensure their robotic investments continue to deliver positive returns over time.

Top 10 Robotic Systems Revolutionizing Industries in 2023

| Robot Type | Industry | Key Features | Impact on Manufacturing | Integration Level |

|---|---|---|---|---|

| Collaborative Robots (Cobots) | Manufacturing | User-friendly, Flexible, Safety Sensors | Increased productivity, Reduced labor costs | High |

| Automated Guided Vehicles (AGVs) | Logistics | Navigation Systems, Load Handling | Streamlined material transport, Enhanced safety | Medium |

| Industrial Robot Arms | Assembly | Precision, Speed, Versatility | Higher throughput, Consistent quality | High |

| Drones | Inspection & Monitoring | Real-time Data Gathering, Aerial View | Lower downtime, Improved Maintenance | Low |

| 3D Printing Robots | Manufacturing | Layering Technology, Customization | Reduced waste, Shorter lead times | Medium |

| Robotic Process Automation (RPA) | Software Automation | Data Processing, Workflow Automation | Efficiency gains, Reduced errors | High |

| Inspection Robots | Quality Control | Image Recognition, Sensor Integration | Improved accuracy, Reduced inspection times | Medium |

| Automated Packaging Systems | Packaging | Speed, Customizable Formats | Lower labor costs, Increased throughput | High |

| Exoskeletons | Healthcare & Manufacturing | Mobility Assistance, Enhanced Strength | Reduced fatigue, Injury prevention | Medium |

| Service Robots | Hospitality & Retail | Customer Interaction, Automated Services | Enhanced customer experience, Cost savings | Medium |

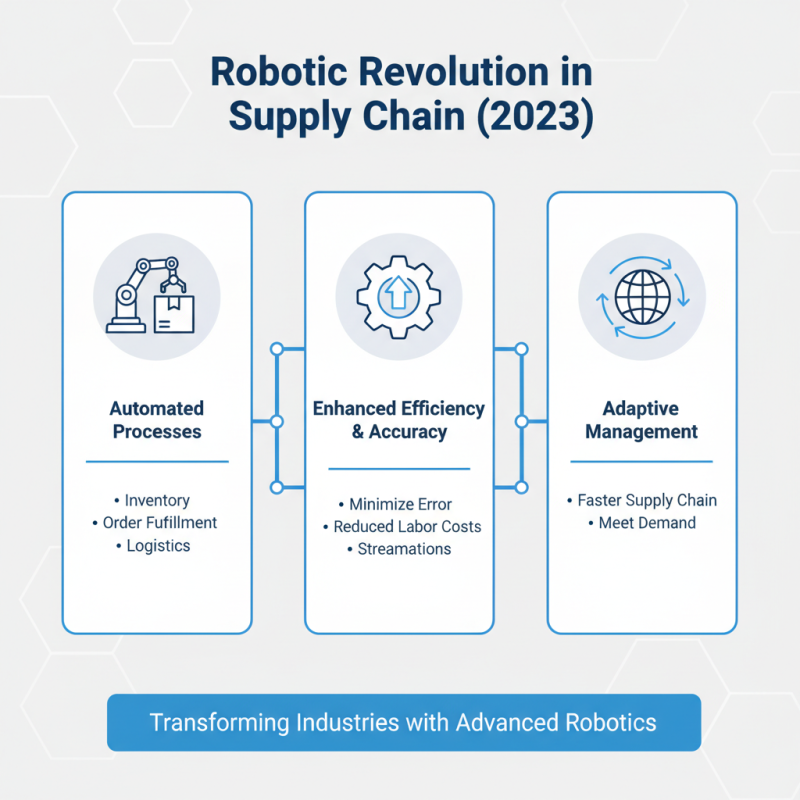

Innovative Robotic Solutions Enhancing Supply Chain Management

The integration of innovative robotic solutions in supply chain management has brought about transformative changes across various industries in 2023. Advanced robotic systems are now capable of automating critical processes such as inventory management, order fulfillment, and logistics, significantly enhancing efficiency and accuracy. By utilizing autonomous robots for tasks like sorting and packaging, companies can minimize human error, reduce labor costs, and streamline operations. This level of automation not only speeds up the supply chain but also allows for more responsive and adaptive inventory management, enabling businesses to meet fluctuating consumer demands effectively.

Moreover, the deployment of robotics in the supply chain offers improved data collection and analysis capabilities. Modern robotic systems are equipped with sensors and AI-driven analytics that monitor and assess performance in real time. This enables companies to gain insights into their operational workflows, identify bottlenecks, and optimize their processes accordingly. The seamless integration of these robotic technologies fosters a resilient supply chain capable of adapting to unforeseen disruptions, whether they arise from changes in market demand or challenges related to logistics. As these innovations continue to evolve, their impact on supply chain efficiency is anticipated to grow, solidifying robotics as a cornerstone of modern industry.

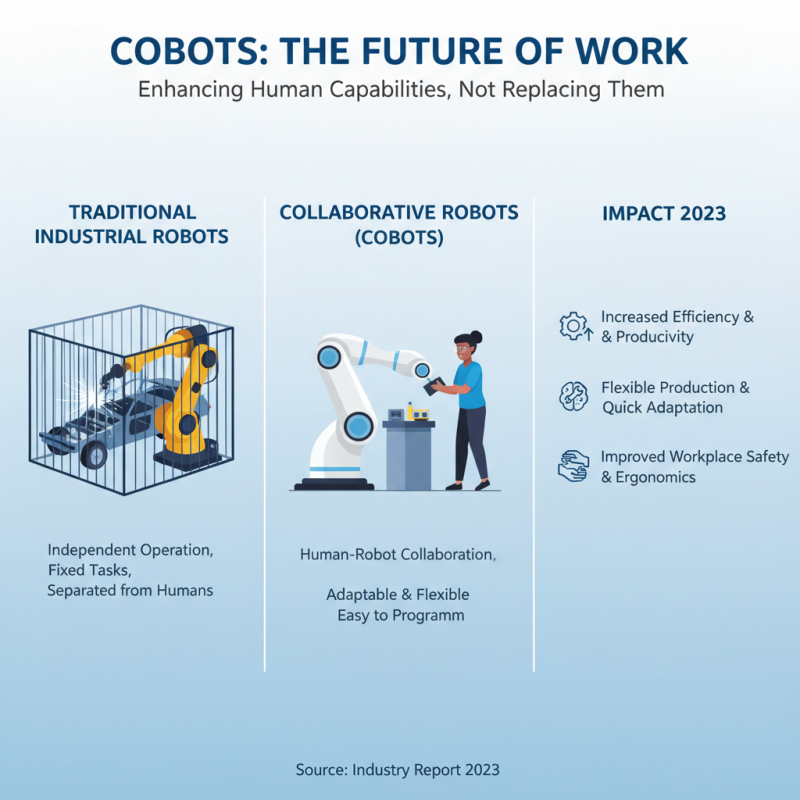

Advancements in Collaborative Robots for Workplace Efficiency

The rise of collaborative robots, or cobots, has marked a significant shift in workplace efficiency and productivity across various industries in 2023. Unlike traditional industrial robots that operate independently, cobots are designed to work alongside human workers, enhancing their capabilities rather than replacing them. This collaboration encourages a more adaptable working environment, as these robots can be easily programmed and reconfigured for different tasks, leading to a quicker response to market demands and a more flexible production line.

Recent advancements in cobot technology have also emphasized safety and ease of use. With sophisticated sensors and artificial intelligence, these machines can assess their surroundings and react to human operators in real-time, significantly minimizing the risk of accidents. The intuitive interfaces allow workers to engage with cobots without extensive training, making them accessible to a broader range of employees. As cobots continue to evolve, they are not only streamlining operations but also fostering a culture of teamwork, where humans and machines collaborate cohesively to propel industries into a more efficient and innovative future.

AI-Powered Robotics in Healthcare: Improving Patient Outcomes

The integration of AI-powered robotics in healthcare is significantly transforming patient outcomes across the globe. According to a recent report by the Institute of Electrical and Electronics Engineers (IEEE), robotic systems equipped with artificial intelligence have been shown to increase surgical precision by up to 30%, thereby reducing the risk of complications and enhancing recovery times for patients. These advanced robotic systems are not only employed in surgical environments but are also making strides in patient monitoring, rehabilitation, and personalized medicine.

Moreover, a study published by the International Journal of Medical Robotics and Computer Assisted Surgery found that AI-driven robotic assistants can analyze vast amounts of patient data to detect early signs of health issues, leading to a 25% improvement in early diagnosis rates. This proactive approach allows healthcare providers to implement timely interventions, ultimately improving patient survival rates and quality of life. As these technologies continue to evolve, their impact on the healthcare industry is expected to grow, making AI-powered robotics a cornerstone in delivering efficient and effective patient care in 2023 and beyond.

Top 10 Robotic Systems Revolutionizing Industries in 2023

This bar chart demonstrates the impact of various AI-powered robotic systems on patient outcomes in healthcare for the year 2023. Each system is rated on a scale from 1 to 10, reflecting its effectiveness in improving health services.

Robotics in Agriculture: Revolutionizing Food Production Techniques

The integration of robotics in agriculture is transforming food production techniques, making them more efficient and sustainable. In 2023, advanced robotic systems are being deployed to address labor shortages and optimize farming practices. These robots are capable of performing a variety of tasks, including planting, harvesting, and even monitoring crop health. By using technologies like precision agriculture and machine learning, these systems can analyze vast amounts of data, enabling farmers to make informed decisions and maximize yields.

Moreover, robotic systems are enhancing the sustainability of food production. By automating labor-intensive tasks, they reduce the reliance on chemical inputs and minimize waste. For instance, autonomous drones equipped with sensors can monitor soil conditions and crop health, allowing for targeted interventions that improve resource management. As a result, farmers are not only increasing productivity but also adopting practices that support environmental conservation. The ongoing evolution in agricultural robotics signifies a promising shift toward smarter, greener farming solutions, ensuring food security for a growing global population.

Related Posts

-

Exploring the Future of Robotic Manufacturing at China's 138th Canton Fair 2025

-

Why Automation Industry is Key to Future Business Success

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Exploring the Future: How Robotic Automation is Revolutionizing Everyday Tasks and Industries

-

Innovative Robotic Solutions Transforming Industries for a Sustainable Future