What is a Robotic Welding Course and Why You Should Take One

In today's rapidly advancing technological landscape, the integration of robotics into various industries has become increasingly prevalent, revolutionizing traditional processes and enhancing efficiency. One such field that has significantly benefited from this robotic revolution is welding. A robotic welding course offers individuals the opportunity to gain essential skills in this innovative area, preparing them for exciting career prospects. As automation continues to reshape the manufacturing sector, understanding robotic welding becomes not just advantageous, but critical for those looking to thrive in this competitive environment.

Participating in a robotic welding course provides comprehensive insights into the principles and applications of robotic welding technologies. Students learn about the programming, operation, and maintenance of robotic welding systems, enabling them to understand how to leverage these tools for optimal performance. This knowledge not only enhances employability but also opens doors to specialized roles that are in high demand, ranging from welding technicians to automation engineers. As industries seek to improve their production processes, the skills acquired from a robotic welding course can lead to a more resilient and rewarding career path.

What is a Robotic Welding Course?

A robotic welding course is designed to equip individuals with the skills necessary to operate and program robotic welding systems effectively. Robotic welding has become increasingly essential in manufacturing, as it dramatically improves efficiency and precision. According to a report by the International Federation of Robotics, the annual growth rate of robotic welding solutions is projected to rise by 10% in the coming years. This indicates a high demand for professionals who are trained in this advanced technology.

Participants in a robotic welding course will learn about various aspects of robotic systems, including programming techniques, equipment setup, and maintenance. Additionally, the course may cover topics such as welding processes, safety protocols, and industry best practices. As industries increasingly adopt automation, having a solid understanding of robotic welding can lead to numerous career opportunities. The American Welding Society reports that skilled welders with robotics training can expect to see their earning potential increase significantly, reflecting the expertise needed in this evolving field. With automation on the rise, investing in a robotic welding course is a strategic move for those looking to advance their careers in engineering or manufacturing.

Robotic Welding Course Enrollments Over the Years

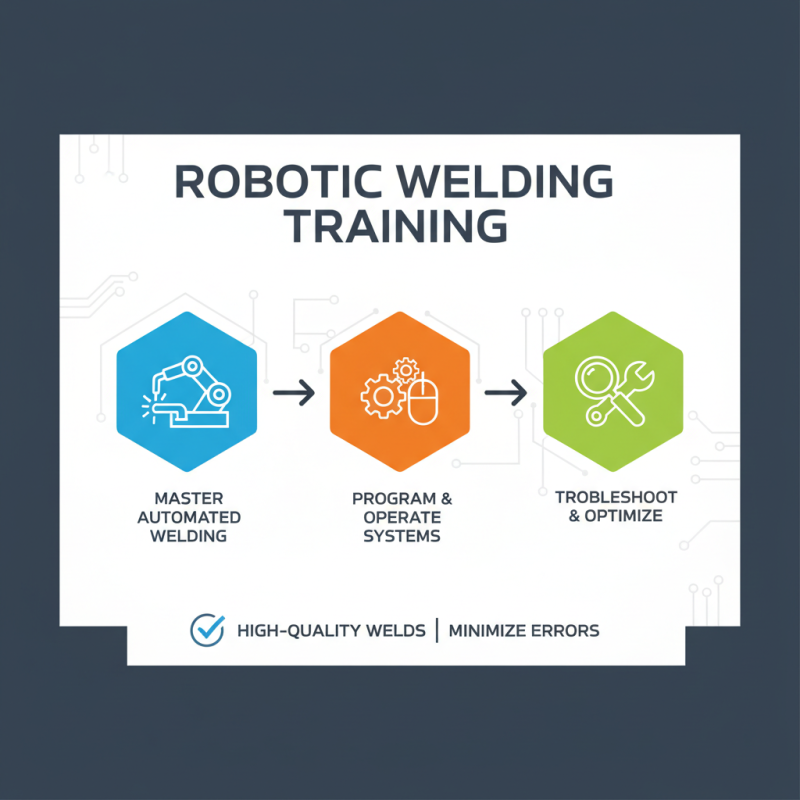

Key Skills and Knowledge Gained from Robotic Welding Training

Robotic welding training offers participants a comprehensive understanding of the principles and techniques essential for mastering automated welding processes. One of the key skills acquired through this training is the ability to program and operate robotic welding systems effectively. Trainees learn how to set up welding parameters, such as speed and angle, and gain proficiency in troubleshooting common issues that may arise during operation. This technical expertise is crucial for ensuring high-quality welds and minimizing errors in production.

In addition to technical skills, a robotic welding course emphasizes the importance of safety and quality control in welding operations. Participants are trained to recognize potential hazards and implement best practices to maintain a safe working environment. Moreover, they develop an understanding of how to conduct inspections and tests to assess the integrity of welds, which is vital in industries where precision and reliability are paramount. By the end of the course, individuals not only become adept at using robotic systems but also enhance their critical thinking and problem-solving abilities, preparing them for advanced roles in manufacturing and engineering fields.

Benefits of Taking a Robotic Welding Course for Career Growth

A robotic welding course can serve as a pivotal tool for individuals seeking to enhance their career prospects in the manufacturing and engineering sectors. As industries rapidly adopt automation technologies, having specialized skills in robotic welding becomes an invaluable asset. Participants in these courses learn the intricacies of robotic welding systems, programming, operation, and maintenance, ensuring they are well-equipped to meet the demands of modern manufacturing environments.

The benefits of taking a robotic welding course extend beyond just technical knowledge. By mastering these advanced welding techniques, individuals can significantly increase their employability and open doors to higher-paying job opportunities. Additionally, the growing trend of automation in industries means that skilled professionals are in high demand, translating to job security and the potential for career advancement. As companies seek to streamline operations and improve efficiency, those proficient in robotic welding will find themselves at the forefront of innovation, making this course a strategic investment for long-term career growth.

What is a Robotic Welding Course and Why You Should Take One - Benefits of Taking a Robotic Welding Course for Career Growth

| Benefits | Description | Impact on Career |

|---|---|---|

| Enhanced Skills | Learn advanced techniques in robotic welding. | Increases employability in high-tech industries. |

| Career Advancement | Prepare for higher-level positions in manufacturing. | Access to supervisor and management roles. |

| Increased Productivity | Utilize robots to enhance production efficiency. | Be seen as an asset to employers focusing on output. |

| Satisfaction in Learning | Gain satisfaction from mastering complex systems. | Enhances job retention and motivation. |

| Networking Opportunities | Meet industry leaders and professionals. | Opens doors to new job opportunities through connections. |

Industries Utilizing Robotic Welding and Job Opportunities

Robotic welding has become an essential technology across various industries, including automotive, aerospace, manufacturing, and construction. These sectors utilize robotic welding for its precision, efficiency, and ability to handle complex tasks that human welders may find challenging. Many automotive manufacturers employ robotic welding for vehicle assembly, taking advantage of its speed and consistency. In the aerospace industry, robots are used for welding lightweight components, ensuring structural integrity while minimizing weight. As industries continue to adopt automation, the demand for skilled professionals who can operate and maintain robotic welding systems has surged.

Tips for individuals considering a course in robotic welding include staying updated on technological advancements in the field. Understanding the latest trends will make you more marketable to potential employers. Additionally, gaining hands-on experience through workshops or internships can significantly improve your practical skills, helping you stand out in a competitive job market. Exploring job opportunities not only in big corporations but also in local businesses and startups can unveil a variety of roles, from robotic technician to quality control inspector.

As companies strive for higher efficiency and lower production costs, the job market for robotic welding specialists continues to grow. Graduates of robotic welding courses can expect to find fulfilling roles in industries that prioritize automation. With many companies investing in advanced manufacturing technologies, the opportunities for career advancement are significant. Continuous learning and adaptability are key components that can help you thrive in this dynamic environment.

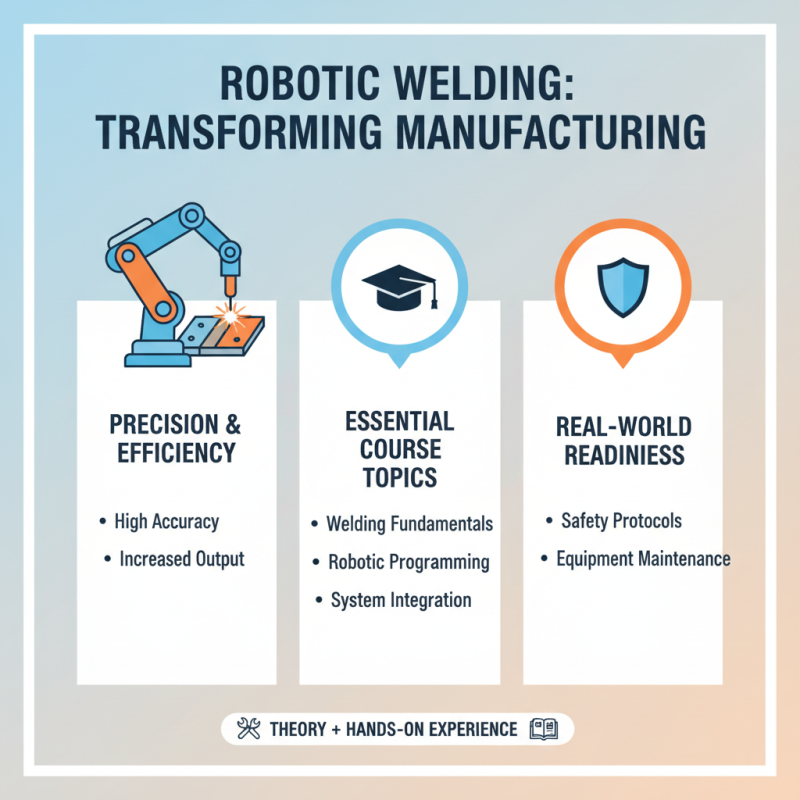

Overview of Robotic Welding Technologies and Techniques in Courses

Robotic welding has transformed the manufacturing landscape, enabling high precision and efficiency in various industrial applications. A robotic welding course introduces students to essential technologies and techniques, encompassing both theoretical knowledge and hands-on experience. Participants explore the fundamentals of welding processes, programming robotic systems, and integrating these machines into production lines. Additionally, courses cover safety protocols and maintenance of robotic equipment, ensuring learners are well-prepared for real-world scenarios.

**Tips:** When selecting a robotic welding course, prioritize programs that offer practical training alongside theoretical learning. Engaging with experienced instructors can significantly enhance your understanding and troubleshooting skills. Furthermore, familiarize yourself with different robotic welding technologies, such as MIG, TIG, and spot welding, as each has unique applications and advantages in the industry.

By mastering advanced robotic welding techniques, students not only gain technical expertise but also become valuable assets to their employers. Through simulations and lab work, learners can develop their skills in programming and operating welding robots, preparing them for exciting career opportunities in automation and manufacturing sectors. Staying updated on the latest advancements in robotic welding technology will also give students a competitive edge, allowing them to adapt to industry changes and innovations efficiently.

Related Posts

-

How to Get Started with Robotic Welding Training for Beginners

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

Top 10 Industrial Automation Solutions Transforming Manufacturing Efficiency

-

Innovative Robotic Solutions Transforming Industries for a Sustainable Future