Top Robotic Welding Systems Trends to Watch in 2025

As we approach 2025, the landscape of robotic welding systems is poised for significant evolution, driven by advancements in technology and shifting industry demands. Experts predict a future where these systems not only enhance efficiency but also reshape the way manufacturers approach welding processes. Dr. Emily Chen, a leading authority in automation technologies, emphasizes the transformative potential of these systems, stating, "The integration of AI and machine learning in robotic welding systems is set to redefine precision and productivity in manufacturing."

The trends we foresee in robotic welding systems include increased automation, improved adaptability to complex geometries, and greater integration of real-time data analytics. These advancements are not merely incremental; they signify a paradigm shift in how industries can leverage automation to enhance quality and reduce costs. Manufacturers are increasingly adopting these technologies to remain competitive, requiring a fresh perspective on existing practices and an openness to innovation.

In summary, the future of robotic welding systems is bright, with several key trends emerging that promise to revolutionize the field. As these technologies continue to develop, they will unlock new possibilities for efficiency, precision, and flexibility in welding applications across various sectors, marking an exciting era for the industry.

Emerging Technologies in Robotic Welding for 2025

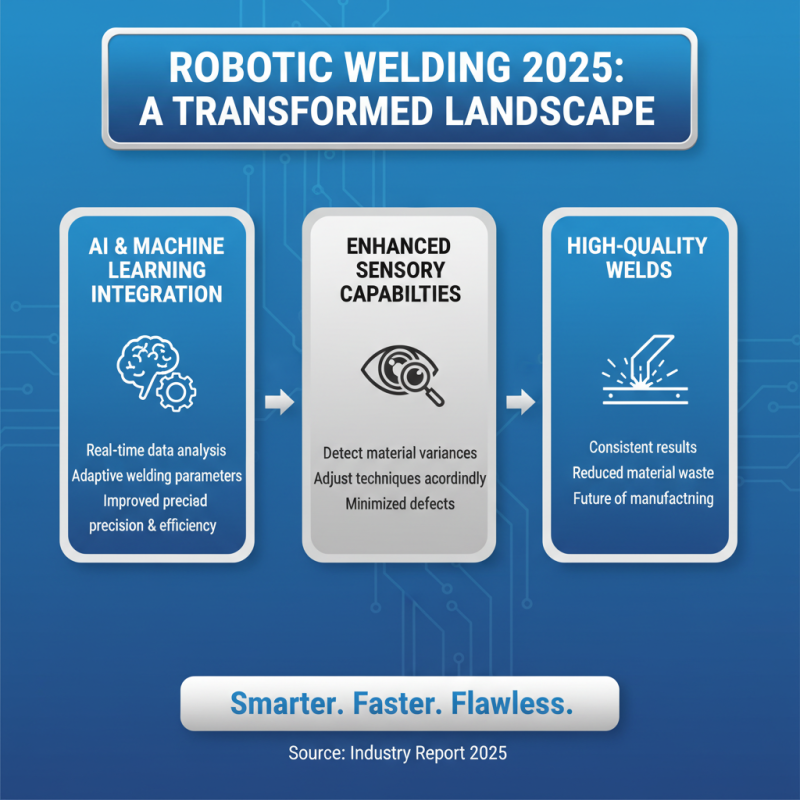

As we look ahead to 2025, the landscape of robotic welding is set to experience significant transformation driven by emerging technologies. One of the most notable trends is the increasing integration of artificial intelligence (AI) and machine learning. These technologies will enable robotic systems to analyze real-time data and adapt their welding parameters on the fly, improving precision and efficiency. With enhanced sensory capabilities, robots will be able to detect variances in material properties and adjust their techniques accordingly, minimizing defects and ensuring high-quality welds.

Another critical development is the rise of collaborative robots, or cobots, in welding applications. Unlike traditional robots that operate in isolation, cobots are designed to work alongside human operators, sharing the workspace and enhancing productivity through teamwork. This synergy will allow for greater flexibility on the production line, enabling quick shifts between different welding tasks without the need for extensive reprogramming. As safety measures and sensor technologies improve, these collaborative systems will become increasingly prevalent in manufacturing environments, making robotic welding more accessible to smaller businesses.

Additionally, advancements in automation software will play a pivotal role in shaping the future of robotic welding. Enhanced programming tools and simulation software will simplify the setup and optimization of welding processes. Companies will be able to create complex weld designs with ease, harnessing virtual reality and design software to visualize the entire welding process before actual implementation. This capability will not only streamline operations but will also facilitate training for operators, resulting in a more skilled workforce equipped to handle sophisticated robotic systems.

Integration of AI and Machine Learning in Robotic Welding Systems

The integration of AI and machine learning in robotic welding systems is set to revolutionize the industry by 2025. According to a recent market report by Research and Markets, the robotic welding market is expected to grow significantly, reaching a valuation of approximately $6 billion by 2025, with AI-driven technologies playing a crucial role in this expansion. The implementation of machine learning algorithms allows robotic systems to learn from past welding operations, optimizing parameters such as speed, electrode positioning, and power settings in real-time, thereby enhancing weld quality and efficiency.

Furthermore, AI-powered robotic welders are becoming increasingly adept at predictive maintenance, utilizing data analytics to foresee equipment failures before they occur. A study by the International Journal of Advanced Manufacturing Technology reveals that predictive maintenance can reduce downtime by up to 30%, leading to substantial cost savings for manufacturers. As these intelligent systems continue to be developed, their ability to adapt to varying materials and welding conditions will improve, fostering versatility in manufacturing processes and supporting the ongoing push for automation in production lines. Overall, the convergence of AI and robotic welding is poised to deliver unprecedented precision, productivity, and reliability in the industry.

Top Robotic Welding Systems Trends to Watch in 2025

This bar chart illustrates the projected adoption rates of key technologies in robotic welding systems, highlighting the integration of AI and machine learning. As industries evolve, the emphasis on smart automation and enhanced efficiency will lead to significant shifts in implementation.

Advancements in Welding Materials and Their Impact on Robotics

The landscape of robotic welding is on the brink of significant transformation as advancements in welding materials are poised to redefine the capabilities of these systems. In 2025, we can expect to see a greater integration of high-performance materials that enhance weld quality and efficiency. Innovations such as lightweight alloys and advanced composites not only improve the mechanical properties of welded structures but also necessitate the development of specialized robotic welding techniques. This evolution will demand that robots be equipped with more adaptive sensors and software capable of adjusting parameters dynamically based on the material being processed.

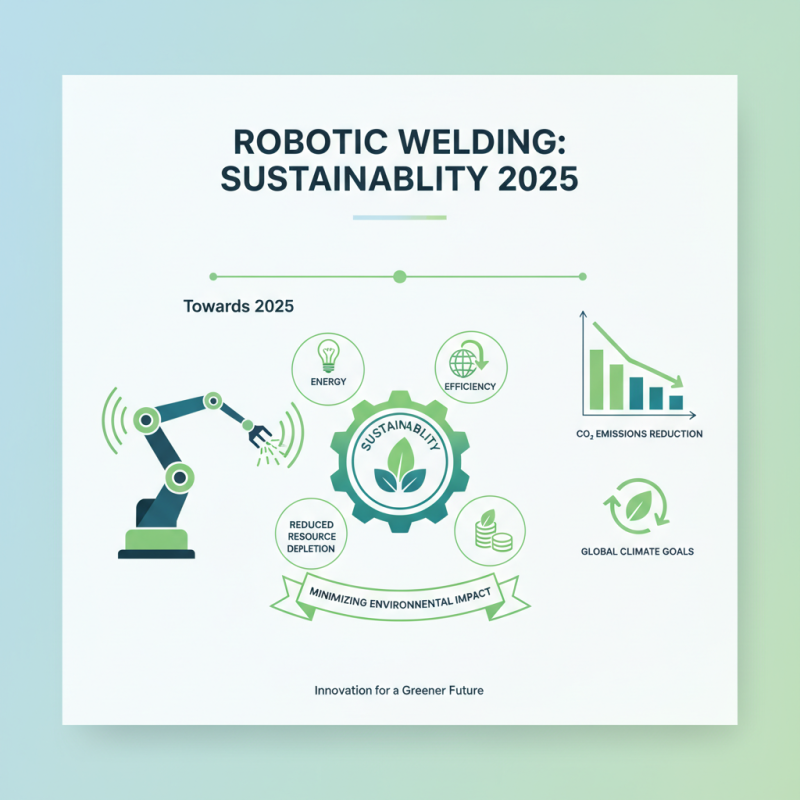

Moreover, the introduction of eco-friendly and sustainable welding materials will play a critical role in shaping the future of robotic welding systems. As industries shift towards greener practices, the demand for materials that reduce environmental impact will grow. Robotics will need to adapt to these new materials, which often have different thermal properties and behavior during the welding process. Consequently, systems that can intelligently manage these newer materials will likely see increased adoption, driving operational efficiency and meeting regulatory requirements. By focusing on material advancements, the robotics industry can optimize processes and deliver solutions that meet both performance and sustainability goals in manufacturing.

Increasing Automation and Its Influence on Workforce Dynamics

As we approach 2025, the landscape of robotic welding systems is evolving rapidly, particularly in the realm of workforce dynamics. The surge in automation is reshaping traditional roles within the manufacturing sector, leading to a redefined workforce. Instead of outright replacement, robotics are increasingly seen as collaborators that enhance human capabilities. Workers are transitioning toward more strategic roles, focusing on overseeing automated processes, troubleshooting, and ensuring quality control. This shift necessitates that companies invest in reskilling their workforce to keep pace with technological advancements.

**Tip:** Companies should implement regular training programs that equip employees with the skills needed to work alongside advanced robotics. This will not only boost productivity but also enhance job satisfaction.

Moreover, the trend towards increased automation in robotic welding is creating a demand for hybrid skill sets. Employees who are adept at both technical and soft skills, such as problem-solving and communication, are becoming invaluable. As robots take on more repetitive tasks, the human element in decision-making and creativity becomes vital. Organizations that recognize this shift and embrace a culture of continuous learning will position themselves favorably in a competitive market.

**Tip:** Encourage a culture of innovation where employees feel empowered to suggest improvements in automated processes. This can lead to greater efficiencies and a more engaged workforce.

Top Robotic Welding Systems Trends to Watch in 2025 - Increasing Automation and Its Influence on Workforce Dynamics

| Trend | Description | Expected Impact |

|---|---|---|

| Increased Integration of AI | Robotic welding systems will incorporate AI to enhance precision and decision-making capabilities. | Improved efficiency and reduced error rates in welding processes. |

| Collaborative Robots | Use of robotic systems that work alongside human operators for increased productivity. | Higher flexibility in operations and enhanced worker safety. |

| Remote Monitoring | Adoption of IoT technologies for monitoring robotic welding systems remotely. | Real-time insights lead to timely maintenance and decreased downtime. |

| Customization Options | Robotic welding systems will offer more customizable features to cater to diverse industries. | Greater versatility in production lines for manufacturers. |

| Sustainability Focus | Shift towards energy-efficient and less wasteful welding technologies. | Reduction in operational costs and increased compliance with environmental regulations. |

Sustainability Trends in Robotic Welding Practices for 2025

As we move towards 2025, sustainability is increasingly becoming a central focus in the field of robotic welding practices. With global concerns about climate change and resource depletion, industries are actively seeking ways to minimize their environmental impact. Robotic welding systems are being designed with energy efficiency in mind, utilizing advanced technologies to reduce consumption during operations. This not only decreases the operational costs but also aligns with the broader environmental goals set by various organizations.

Furthermore, the integration of eco-friendly materials and processes is a significant trend. Manufacturers are exploring the use of recyclable materials and innovative welding techniques that produce less welding fume and waste. By implementing these sustainable practices, companies can improve their production efficiency while adhering to stringent environmental regulations. As more organizations recognize the importance of sustainability, robotic welding systems will play a crucial role in fostering a cleaner, greener manufacturing environment, paving the way for future innovations in the industry.

Related Posts

-

Revolutionize Your Manufacturing Process with the Latest FANUC Welding Robot Innovations

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency

-

How to Optimize Robotic Welding Processes for Maximum Efficiency and Quality

-

Unlocking Efficiency in Manufacturing with Fanuc Welding Robots for Precision and Productivity

-

How to Improve Your Robotic Welding Techniques for Better Results