How to Get Started with Robotic Welding Training for Beginners

Robotic welding training has become an essential skill in today's manufacturing landscape, particularly as industries increasingly turn to automation to enhance productivity and efficiency. For beginners eager to enter this field, understanding the basics of robotic systems and their applications in welding is crucial. This advanced technology not only streamlines the welding process but also ensures higher precision and consistency, making it a valuable addition to any welding operation.

Embarking on your journey into robotic welding can be both exciting and overwhelming. It involves not just the technical aspects of operating robotic systems, but also grasping the underlying principles of welding itself. Whether you are a newcomer looking to develop your skills or a professional seeking to expand your expertise, a well-structured training program can provide the foundational knowledge and hands-on experience necessary to succeed. By focusing on the principles of robotic welding, aspiring technicians can position themselves at the forefront of an evolving industry, ultimately paving the way for career advancement and opportunities in various sectors.

Understanding the Basics of Robotic Welding Technology

Robotic welding technology has revolutionized the manufacturing industry by enhancing efficiency and precision in welding processes. At its core, robotic welding involves the use of automated welding systems to perform tasks that traditionally required human intervention. Understanding the basics of this technology is crucial for beginners looking to engage in welding training. A fundamental aspect of robotic welding includes familiarization with the various types of robotic arms and controllers, which are designed to carry out specific welding methods such as MIG, TIG, and laser welding.

Another important factor is grasping the software that drives robotic welding machines. This includes programming languages and interfaces that allow operators to define welding paths, manage settings, and troubleshoot issues. Beginners should also learn about the different sensors and safety measures integrated into robotic welding systems, which ensure high-quality welds while minimizing risks. By focusing on these essential components, newcomers can build a solid foundation for further exploration of robotic welding technology, paving the way for more advanced skills and applications in automated manufacturing.

Robotic Welding Training Fundamentals

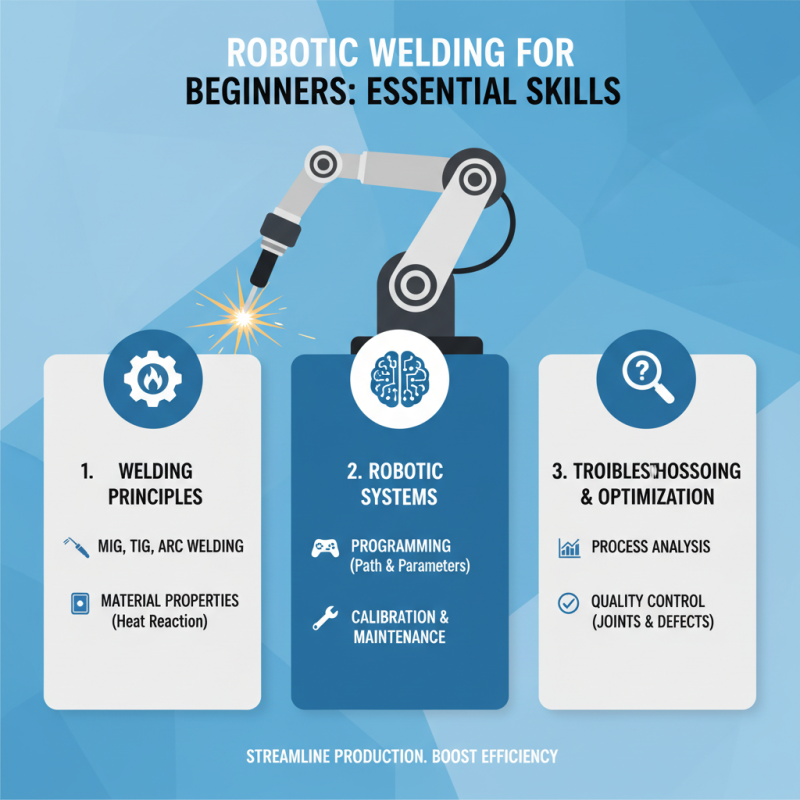

Identifying Essential Skills and Knowledge for Beginners

Robotic welding is a transformative technology that streamlines production processes in various industries. For beginners looking to embark on this journey, understanding the essential skills and knowledge is crucial. Firstly, a fundamental grasp of welding principles is necessary. This includes familiarity with different welding methods such as MIG, TIG, and arc welding. Knowledge of materials and their properties, especially how they react under heat, is also vital. This foundational understanding will help beginners not only operate robotic systems but also troubleshoot and optimize the welding process.

In addition to technical knowledge, beginners must develop skills in programming and operating robotic systems. Understanding CAD (Computer-Aided Design) software is essential, as it allows operators to create and modify welding paths. Moreover, familiarity with the specific robotic welding equipment is necessary. This includes learning how to set up the machine and perform routine maintenance. Safety protocols and practices should not be overlooked, ensuring that operators can maintain a safe working environment while maximally leveraging robotic technology. By focusing on these essential skills and knowledge areas, beginners can effectively prepare themselves for a successful career in robotic welding.

Choosing the Right Robotic Welding Training Program

When selecting the right robotic welding training program, it’s essential to consider the specific needs of both the industry and the individual learner. The global robotic welding market is projected to grow from $4.06 billion in 2020 to $10.58 billion by 2026, according to a report by Mordor Intelligence. This significant growth underscores the increasing demand for skilled workers who are proficient in robotic welding. Therefore, choosing a program that offers hands-on training with the latest technologies and equipment can greatly enhance job readiness.

It’s also crucial to evaluate the curriculum and accreditations of the training program. Programs that align with industry standards and are recognized by reputable organizations can provide learners with a credible foundation. For example, the American Welding Society (AWS) offers certification that is highly regarded in the industry. Programs incorporating this certification not only enhance a student's resume but also ensure that they are well-versed in the best practices and safety protocols that are crucial for success in robotic welding. Opting for training that includes both theoretical knowledge and practical applications will ultimately prepare beginners for the evolving demands of the workforce.

Hands-On Practice: Workshops and Simulation Training

Hands-on practice is crucial for anyone looking to excel in robotic welding, particularly for beginners. Workshops specifically designed for robotic welding training provide an immersive learning environment where participants can engage with the latest technologies. According to a report by the International Federation of Robotics (IFR), the demand for robotic welding is projected to grow annually by 14% over the next five years, emphasizing the need for well-trained professionals in the industry.

Simulation training complements hands-on experience by allowing trainees to practice in a risk-free digital environment. By utilizing sophisticated welding simulators, learners can understand the intricacies of robotic welding without the costs associated with material waste or equipment damage. A recent industry survey revealed that 70% of companies reported improved training outcomes when incorporating simulation into their programs. This dual approach not only reinforces theoretical knowledge but also builds the practical skills necessary for effective robotic welding.

Evaluating Career Opportunities in Robotic Welding Industries

Robotic welding is swiftly emerging as a crucial technology in various industries, presenting a plethora of career opportunities for individuals seeking to enter this field. According to a report by the International Federation of Robotics, robotic automation, including welding, is projected to grow at an annual rate of 13% through 2025. This surge is largely driven by the automotive and manufacturing sectors, which are increasingly adopting automated solutions to enhance efficiency, precision, and safety in production processes. As industries evolve, there is an increasing demand for skilled professionals who can effectively operate and maintain robotic welding systems.

In addition to the growth in demand for robotic welding, the Bureau of Labor Statistics forecasts that employment of welding, soldering, and brazing workers could increase by 3% from 2020 to 2030. This statistic underscores the importance of specialized training programs that equip beginners with the necessary skills in robotic welding technologies. Institutions are now offering comprehensive training courses that blend theoretical knowledge with hands-on experience, preparing participants for roles ranging from robotic welder to automation engineer. As the landscape of manufacturing continues to change, obtaining training in robotic welding not only enhances job prospects but also opens avenues for career advancement in a rapidly evolving field.

Related Posts

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Revolutionizing Learning How Robotic Training Enhances Skill Development and Employment Opportunities

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Unlocking the Future: 2025 Trends in Robotic Programming for Enhanced Automation

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency