Top 10 Tips for Mastering Robotic Spot Welding Techniques

In the rapidly evolving landscape of manufacturing, robotic spot welding has emerged as a crucial technique, facilitating precision and efficiency in the production process. According to a report by MarketsandMarkets, the global robotic welding market is projected to grow from USD 4.2 billion in 2020 to USD 6.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.5%. This growth is driven by the increasing demand for automation in industries such as automotive, electronics, and heavy machinery. As robotic spot welding systems continue to advance, mastering the techniques associated with their operation becomes essential for manufacturers looking to optimize productivity and maintain a competitive edge.

Employing robotic spot welding not only enhances welding quality but also significantly reduces labor costs and cycle times. A study published by the International Federation of Robotics highlights that companies adopting robotic technologies have experienced productivity improvements of up to 30%. However, to fully harness these benefits, operators and engineers must be equipped with the right skills and knowledge. This article aims to present the top 10 tips for mastering robotic spot welding techniques, empowering professionals to navigate the complexities of this technology and maximize its potential within their operations. As we delve into these strategies, the importance of continuous learning and adaptation in the face of technological advancements will be underscored, ensuring sustained growth and improvement in manufacturing settings.

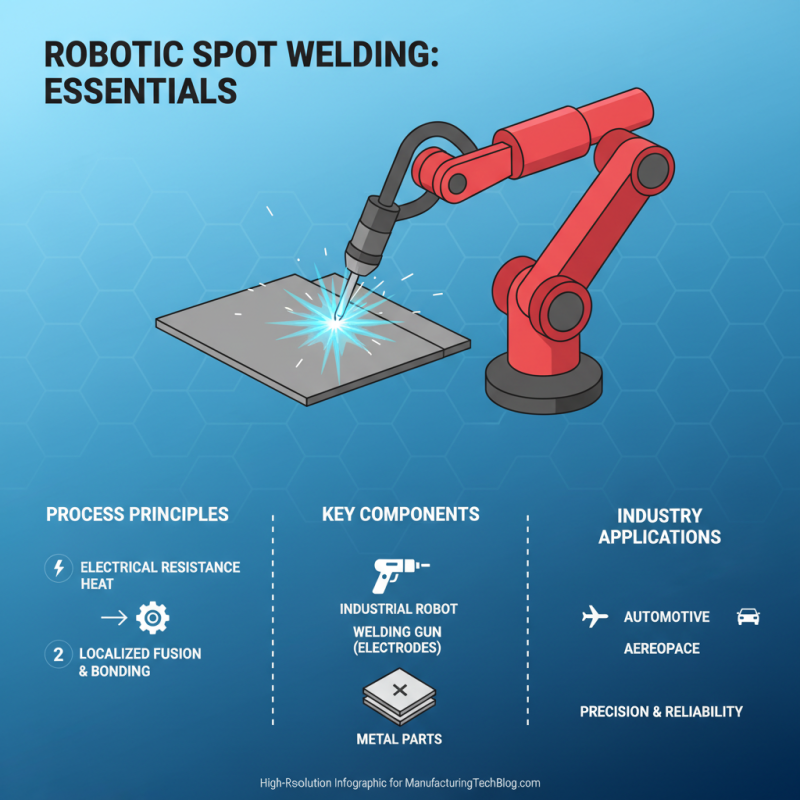

Understanding the Basics of Robotic Spot Welding Techniques

Robotic spot welding is a crucial manufacturing technique, particularly in the automotive and aerospace industries, where precision and reliability are paramount. Understanding the basics of this process involves familiarizing oneself with the fundamental components and principles that drive robotic spot welding operations. At its core, spot welding relies on the application of heat generated from electrical resistance to join two or more metal parts. The welding gun, equipped with electrodes, creates a localized fusion at the joint area, forming a strong bond that is essential for structural integrity.

In addition to mastering the mechanics of the welding equipment, operators must also grasp the various parameters that influence the quality of the weld. Key factors such as electrode pressure, welding time, and electrical current must be finely tuned to achieve consistent results. Knowledge of the materials being welded is equally important, as different metals and thicknesses require specific settings to ensure optimal bonding. By developing a solid foundation in these fundamental aspects of robotic spot welding, practitioners can significantly enhance their proficiency and contribute to the efficiency and quality of manufacturing processes.

Essential Equipment for Effective Robotic Spot Welding

When it comes to robotic spot welding, having the right equipment is crucial for ensuring efficiency and precision in your operations. The essential components include the robotic arm itself, which should have the capability to perform accurate movements and adjustments. An advanced control system enhances the arm's performance, enabling seamless integration with various welding materials and geometries. Additionally, a reliable power source that can deliver consistent energy is vital, as it directly impacts the quality of the welds produced.

Another important piece of equipment is the welding gun or electrode, which needs to be tailored to the materials being joined. The selection of the proper electrode ensures optimal heat distribution and penetration, which are crucial for strong welds. Moreover, incorporating necessary safety features, such as protective guards and automated features that minimize risk during operation, can greatly enhance the overall effectiveness of the robotic spot welding system. Investing in top-quality equipment not only improves the welding process but also increases the longevity of the machinery, making it a worthwhile consideration for any manufacturing environment.

Key Variables Affecting Spot Welding Quality

The quality of robotic spot welding is significantly influenced by several key variables that must be meticulously controlled to achieve optimal results. One of the primary factors is the electrode force, which determines the amount of pressure applied to the materials being joined. Insufficient force may result in weak welds, while excessive pressure can cause damage to both the electrode and the workpieces. Maintaining the correct balance is essential for ensuring a solid and reliable weld.

Another critical variable is the welding current and duration. The intensity of the current and the length of time it is applied affect the heat generated during the welding process. Too little current or a short duration may not provide enough heat to melt the materials effectively, leading to insufficient fusion. Conversely, excessive current or prolonged exposure can lead to overheating, which can cause burn-through or warping. It is crucial to fine-tune these parameters based on the thickness and type of materials being welded to attain consistent quality.

Additionally, the cleanliness of the surfaces being joined cannot be overlooked. Oxidation, dirt, or any contaminants can inhibit proper adhesion and lead to weak spots in the weld. Regular maintenance and preparation of the work surfaces are necessary to ensure that the materials are free from any impurities that could compromise the quality of the joint. By focusing on these variables—electrode force, welding current and duration, and surface cleanliness—operators can enhance the effectiveness and reliability of robotic spot welding processes.

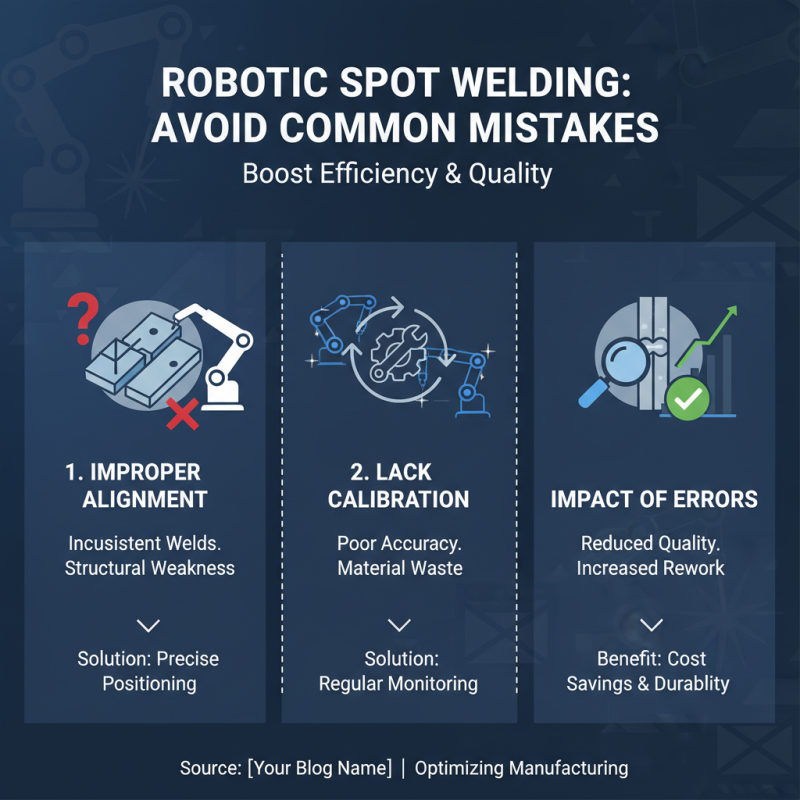

Common Mistakes to Avoid in Robotic Spot Welding

When mastering robotic spot welding techniques, it's crucial to be aware of common mistakes that can hinder efficiency and quality. One prevalent error is improper alignment of the workpieces. Misalignment can cause inconsistent welds, leading to structural weaknesses. Ensuring precise positioning not only improves weld quality but also minimizes rework and material waste. Regular calibration and monitoring of the robotic arm can aid in achieving optimal alignment.

Another frequent mistake is overlooking the importance of maintaining proper welding parameters, such as pressure, electric current, and weld time. Deviating from the ideal settings can result in weak or overly fused joints. It's advisable to continuously review and adjust these parameters based on the materials being welded. Conducting regular training sessions for operators can also enhance their understanding of how to optimize these settings effectively.

Lastly, neglecting the condition of the welding tips can lead to poor performance and increased costs. Worn or damaged tips can result in inconsistent welds and longer cycle times. Routine inspections and timely replacements are essential to maintain high-quality welding operations. By staying vigilant about these common pitfalls, teams can significantly improve their robotic spot welding outcomes and achieve greater production efficiency.

Best Practices for Maintenance and Calibration of Welding Robots

Maintaining and calibrating robotic welding machines is crucial for ensuring optimal performance and longevity. According to the International Federation of Robotics (IFR), approximately 77% of all industrial robots are used in manufacturing processes, highlighting the importance of robust maintenance practices to prevent downtime. Regular maintenance not only helps in identifying potential issues before they escalate but also ensures that welding robots operate at peak efficiency. Industry standards recommend conducting checks on key components, such as the welding torch and power supply, at least once every six months to ensure they are functioning correctly.

Calibration is another fundamental aspect of robotic welding, directly impacting the quality and precision of welds. Misalignment can lead to weak joints and increased rework costs, which, as per a report by the American Welding Society (AWS), can account for up to 10% of total welding expenses. Implementing a routine calibration schedule helps maintain accurate settings and enhances consistency in weld quality. Best practices suggest utilizing calibration tools and software that are specifically designed for robotic systems, enabling more precise adjustments that conform to the specified tolerances of the project.

Overall, investing in structured maintenance and calibration protocols is essential for manufacturing facilities seeking to optimize their robotic welding operations. Data indicate that companies that prioritize these practices can experience up to a 25% reduction in operational costs and a significant increase in production quality, underscoring the substantial benefits of proactive management strategies in robotic welding applications.

Related Posts

-

Revolutionizing Manufacturing with Robotic Welding Machines for Enhanced Efficiency

-

What is Robotic Welding Solutions? Exploring Automation in the Welding Industry with Data Insights

-

Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

-

2025 Top 10 Robotic Welding Systems Revolutionizing Manufacturing Efficiency

-

Exploring the Future: How Robotic Automation is Revolutionizing Everyday Tasks and Industries

-

What is a Robotic Welding Course and Why You Should Take One