Top Industrial Automation Solutions Driving 2026 Innovations?

The landscape of industrial automation solutions is rapidly evolving. By 2026, these innovations aim to reshape industries and enhance productivity. Automation technologies have gained traction, allowing businesses to streamline operations and minimize human error. The integration of artificial intelligence and machine learning is a game changer. These tools can analyze vast amounts of data, leading to informed decision-making.

However, as we delve deeper into these advancements, concerns arise. Not every solution fits every business. Some companies may struggle to adapt to new systems. Challenges in training staff and integrating technologies can hinder progress. It is crucial to critically assess the specific needs before implementation. The road to innovation often comes with bumps.

In this exploration of industrial automation solutions, we will examine key trends, potential pitfalls, and the impact these technologies could have on various sectors. It's an exciting time for industries eager to innovate, but also a moment for caution and reflection. Balancing ambition with practicality is essential as we forge ahead into this dynamic future.

Innovative Technologies Shaping Industrial Automation by 2026

The landscape of industrial automation is evolving rapidly. By 2026, several innovative technologies will reshape this sector, driving efficiency and productivity. The integration of artificial intelligence brings advanced data analytics. Machines learn from patterns, optimizing processes in real-time.

Robotics is also advancing quickly. Collaborative robots, or cobots, work alongside humans safely. They can handle repetitive tasks, allowing workers to focus on complex problems. However, the challenge remains in training staff to adapt to these changes. Employees may feel uncertain about their roles in an automated environment.

Internet of Things (IoT) is another game-changer. Connected devices provide valuable insights into operations. Predictive maintenance reduces downtime, but it requires a cultural shift within organizations. Companies must rethink their approach to data security and privacy. Embracing these innovations is essential, yet it comes with its own set of challenges.

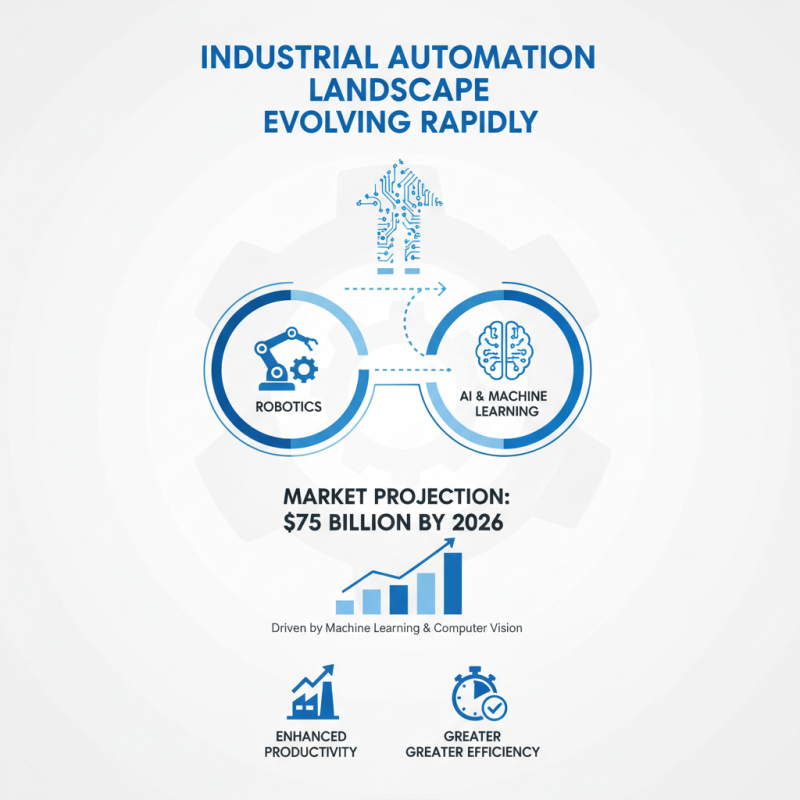

Emerging Trends in Robotics and AI for Industrial Applications

The landscape of industrial automation is changing rapidly. Robotics and AI are at the forefront of this transformation. Recent industry reports suggest that the market for industrial robots is projected to reach $75 billion by 2026. This growth is driven by advancements in machine learning and computer vision. Manufacturers are increasingly integrating these technologies for enhanced productivity and efficiency.

AI's role in predictive maintenance is gaining attention. Studies indicate that predictive maintenance can reduce downtime by up to 30%. However, companies often underestimate the data quality needed for successful implementation. Inadequate data can lead to false predictions and wasted resources. It's a crucial area for improvement.

Emerging trends highlight a push towards collaborative robots, or cobots. These machines work alongside humans, ensuring safety and enhancing workflows. Yet, challenges remain in achieving seamless human-robot collaboration. Employees may fear job losses due to automation. Open dialogue is essential to address these concerns and foster a culture of innovation. The future of industrial automation hinges on balancing technology with human elements.

Advancements in IoT and Connectivity Enhancing Automation Solutions

The industrial landscape is undergoing a significant transformation. The integration of IoT and enhanced connectivity plays a crucial role in this shift. These technologies create an interconnected environment that enables machines and systems to communicate seamlessly. This communication allows for real-time data exchange, making operations smarter and more efficient.

However, there are challenges to consider. Not every factory is ready for this level of connectivity. Some struggle with outdated systems that resist modernization. Additionally, security remains a concern. With more devices connected, the potential for cyber threats increases. Companies must think carefully about their network vulnerabilities.

As innovations evolve, automation solutions become more sophisticated. Predictive maintenance is one promising area. Sensors can now predict when equipment will fail. This reduces downtime and saves costs. Still, the reliance on technology raises questions. How much dependence is too much? Striking the right balance is vital for future success.

Top Industrial Automation Solutions Driving 2026 Innovations

This chart illustrates the projected advancements in key dimensions of industrial automation solutions by 2026, focusing on the impact of IoT and connectivity enhancements.

Impact of Data Analytics on Industrial Efficiency and Decision-Making

Data analytics is reshaping industrial automation. It enhances efficiency and improves decision-making. With better insights, businesses can optimize processes. Data helps identify trends and potential areas for improvement. Companies that embrace data analytics see significant gains.

Implementing data-driven strategies requires effort. Start by integrating data collection tools. Ensure that your workforce understands data interpretation. This can be challenging. Some team members may resist change. Training sessions can help bridge this gap. Engagement is key.

Regularly review your analytics processes. Mistakes can happen, leading to inaccurate conclusions. Reflect on your data sources and methodologies. Ensure you're not missing valuable insights. Keep in mind, analytics is not just about numbers; it's about fostering a culture of continuous improvement.

Sustainable Practices and Their Role in Future Automation Developments

Sustainable practices are becoming crucial in industrial automation. A recent report indicates that 72% of businesses prioritize sustainability in their automation strategies. Companies now seek to reduce waste and energy consumption. This shift reflects a growing awareness of environmental impact.

For instance, integrating renewable energy sources into manufacturing processes can lower carbon footprints. Automation technologies like AI and IoT also help optimize resource use. Reports suggest that firms using automation can reduce energy costs by up to 30%. Yet, the transition is not without challenges. Many businesses struggle with upfront costs and adapting existing systems.

Moreover, achieving sustainability often requires culture change within organizations. Employees may resist new practices. Training and education become essential for successful implementation. Companies must maintain a balance between innovation and environmental responsibility. Developing truly sustainable solutions demands ongoing reflection and adaptation.

Top Industrial Automation Solutions Driving 2026 Innovations

| Solution Type | Sustainability Impact | Innovation Label | Adoption Rate (%) | Projected Cost Savings |

|---|---|---|---|---|

| AI & Machine Learning | Reduce energy consumption | Smart Analytics | 75% | $500,000 annually |

| Robotics Automation | Enhance efficient resource usage | Eco-friendly Robotics | 65% | $300,000 annually |

| IoT Solutions | Optimize waste management | Connected Systems | 80% | $400,000 annually |

| Cloud Computing | Lower carbon footprint | Flexible Infrastructure | 70% | $250,000 annually |

| Digital Twins | Minimize resource waste | Sustainable Simulation | 60% | $350,000 annually |

Related Posts

-

How to Choose the Best Industrial Automation Solutions for Your Business Needs

-

Top 10 Industrial Automation Solutions Transforming Manufacturing Efficiency

-

Unlocking Growth: Industrial Automation Solutions at China's 138th Canton Fair 2025

-

Exploring Industrial Automation Solutions at the 2025 China Import and Export Fair with Key Industry Insights

-

Exploring Industrial Automation Solutions at the 138th Canton Fair China 2025 Industry Insights

-

Exploring Industrial Automation Solutions at the 138th Canton Fair 2025 Insights and Innovations