Top 10 Industrial Robots Transforming Manufacturing in 2023

As we navigate through 2023, the landscape of manufacturing is undergoing a remarkable transformation, largely driven by advancements in technology. At the forefront of this revolution are industrial robots, which are redefining efficiency, precision, and productivity on factory floors around the globe. These sophisticated machines are not only enhancing the speed at which products are manufactured but also improving the quality of these products by minimizing human error and optimizing processes.

The integration of industrial robots into manufacturing is paving the way for smarter factories that leverage automation to meet the ever-increasing demand for customization and rapid delivery. With their ability to perform repetitive tasks with unwavering consistency, industrial robots are enabling companies to reallocate human resources toward more strategic roles, thereby fostering a culture of innovation and creativity. As we explore the top ten industrial robots that are making waves in the manufacturing sector this year, it becomes clear that these technological marvels are not just tools—they are key enablers of a future where manufacturing is more agile, efficient, and responsive to market needs.

The Rise of Collaborative Robots in Modern Manufacturing Processes

The rise of collaborative robots, or cobots, is reshaping manufacturing processes in 2023. Unlike traditional industrial robots that operate independently and often in isolation, cobots are designed to work alongside human workers. This paradigm shift not only enhances productivity but also emphasizes safety and adaptability in the workplace. Cobots can take on repetitive and strenuous tasks, allowing human operators to focus on more complex and value-added activities, thereby improving overall efficiency and job satisfaction.

In modern manufacturing environments, the integration of cobots is evident across various sectors. These robots are equipped with advanced sensors and AI capabilities, enabling them to learn from their human counterparts and operate seamlessly in dynamic settings. This technological advancement fosters a collaborative atmosphere where humans and machines can exchange tasks fluidly. As a result, manufacturers can achieve higher precision and quality in their outputs, all while reducing the incidence of workplace injuries. The adaptability of cobots to different tasks and environments makes them essential tools for industries aiming to stay competitive in an ever-evolving market landscape.

Top 10 Industrial Robots Transforming Manufacturing in 2023

| Robot Model | Type | Payload Capacity (kg) | Reach (mm) | Applications |

|---|---|---|---|---|

| Model A | Collaborative | 10 | 1200 | Assembly, Packaging |

| Model B | Articulated | 20 | 1500 | Welding, Painting |

| Model C | SCARA | 5 | 800 | Pick and Place, Assembly |

| Model D | Delta | 3 | 600 | Packaging, Sorting |

| Model E | Collaborative | 12 | 1000 | Machine Tending, Quality Control |

| Model F | Cartesian | 15 | 1200 | Material Handling, Picking |

| Model G | Collaborative | 8 | 900 | Assembly, Collaborative Tasks |

| Model H | Articulated | 25 | 1600 | Machining, Heavy Tasks |

| Model I | SCARA | 10 | 750 | Automated Assembly, Packaging |

| Model J | Delta | 4 | 500 | High-Speed Sorting, Packaging |

Enhancing Efficiency: The Role of Autonomous Mobile Robots in Factories

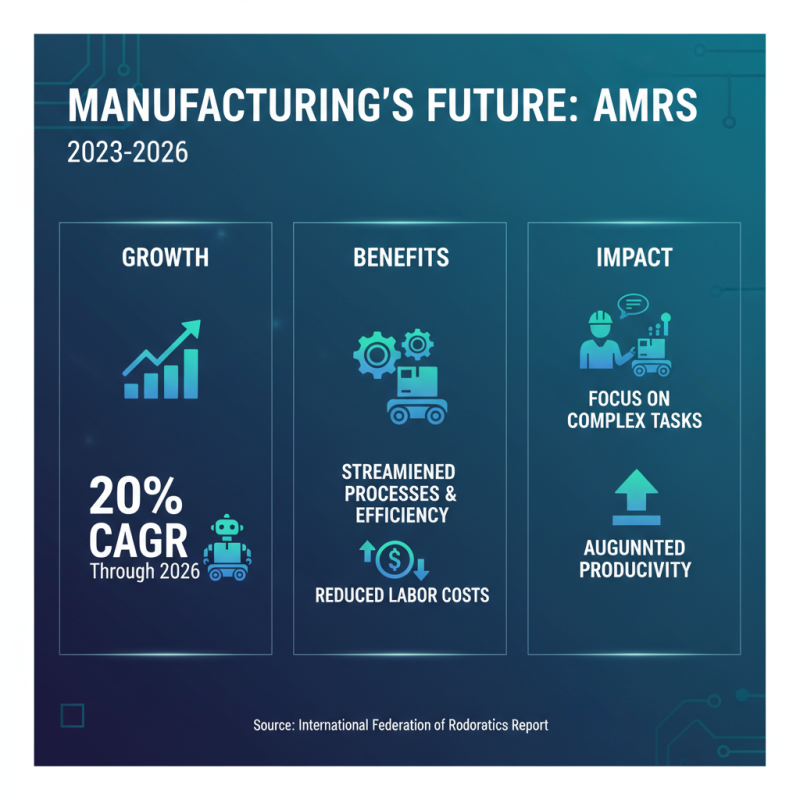

In 2023, the manufacturing landscape is increasingly shaped by the integration of Autonomous Mobile Robots (AMRs), which play a crucial role in enhancing operational efficiency. According to a report by the International Federation of Robotics, the adoption of AMRs in manufacturing is projected to grow at a CAGR of 20% through 2026, with factories recognizing their ability to streamline processes and reduce labor costs. These robots excel in navigating dynamic environments, allowing for quicker and safer material handling. By automating repetitive tasks, AMRs free human workers to focus on more complex and value-added activities, thereby augmenting productivity levels in the manufacturing sector.

The impact of AMRs is particularly evident in warehouse operations, where they can significantly reduce the time spent on inventory management and transportation. Data from Logistics Management indicates that companies deploying AMRs have seen inventory picking speeds increase by up to 400%, while also minimizing errors and damage during handling. Furthermore, these robots adapt intelligently to their surroundings, using advanced sensors and machine learning algorithms to optimize routes and enhance safety. This adaptability is vital as the manufacturing industry faces growing demands for flexibility and responsiveness, ultimately transforming how factories operate and compete in the market.

Impact of AI-Powered Robotics on Production Speed and Accuracy

The rise of AI-powered robotics in manufacturing has significantly transformed production dynamics in 2023. These advanced robots enhance production speed and accuracy by leveraging machine learning algorithms and real-time data analytics. This allows them to not only adapt to varying workloads but also to predict machine failures and adjust tasks proactively, leading to a more efficient manufacturing process. The integration of AI enables robots to learn from their experiences, thereby increasing their precision over time and reducing human error in intricate tasks.

Tips for manufacturers looking to implement AI-powered robotics include starting small. Begin with a pilot program that targets specific bottlenecks in your production line. This approach allows for easier troubleshooting and adaptation before fully integrating AI solutions across the entire operation. Additionally, invest in training for your workforce to adapt to these new technologies. Understanding how to work alongside AI systems can maximize their benefits and drive productivity.

Another critical aspect is monitoring and analyzing the performance of AI-powered robots regularly. Continuous evaluation helps identify areas for further improvement and ensures the technology is being leveraged to its fullest potential. By keeping a close eye on production metrics, manufacturers can refine processes and enhance overall operational efficiency, fostering a culture that embraces innovation within the workforce.

Key Metrics: Cost Savings Achieved by Implementing Industrial Robots

The integration of industrial robots in manufacturing has risen significantly in 2023, with numerous companies reaping the benefits of automation. One of the most compelling reasons for this transition is the substantial cost savings that can be achieved. By implementing robotic systems, manufacturers have been able to reduce labor costs, minimize errors, and enhance production efficiency. For instance, robots can work around the clock without the need for breaks, leading to increased output and lower unit costs over time.

Moreover, the initial investment in robotic technology has become more accessible due to advancements in automation solutions and a competitive marketplace. Companies are reporting noticeable reductions in operational expenses, with some estimating up to 30% savings in labor costs alone. These savings are further complemented by decreased waste generation and improved product quality, which significantly contributes to the overall profitability of manufacturing operations. With the continual evolution of robotic capabilities, businesses that adopt these technologies are positioned not only to save costs but also to remain competitive in an ever-evolving market landscape.

Future Trends: The Integration of IoT with Robotics in Manufacturing

The integration of the Internet of Things (IoT) with robotics is revolutionizing the manufacturing landscape. As machines become smarter and more interconnected, the ability to collect and analyze real-time data has significantly enhanced production efficiency. By equipping industrial robots with IoT capabilities, manufacturers can monitor performance metrics, predict maintenance needs, and optimize workflows. This connectivity allows for quicker responses to changes in demand, ultimately leading to a more agile and responsive production environment.

The synergy between IoT and robotics paves the way for advanced automation. With sensors gathering data from various points in the manufacturing process, robots can make informed decisions autonomously, reducing downtime and enhancing precision. Furthermore, the continuous feedback loop created by IoT enables manufacturers to refine their processes dynamically, leading to improved quality control and reduced waste. As this trend continues to evolve, the role of industrial robots in achieving smarter and more sustainable manufacturing practices will become increasingly significant, positioning organizations for future success in a competitive landscape.

Related Posts

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Exploring the Future of Automation: How Robot Machines are Revolutionizing Industry Efficiency

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Exploring Industrial Automation Solutions at the 138th Canton Fair China 2025 Industry Insights

-

Innovative Robotic Solutions Transforming Industries for a Sustainable Future

-

Revolutionizing Efficiency: How Automation Machines Are Shaping the Future of Manufacturing in 2023